BOWLES TRAILERS AND TRANSFER STATION EQUIPMENT

To round out Bowles' extensive line of refuse collection equipment, the company also manufactured long-haul transfer trailers, most with ejection plates. Bowles also designed and built compete transfer stations for the centralized collection and transport of refuse. Demand for transfer stations increased during the 1960s as disposal points moved from incinerators within city limits, to more distant locations where landfill sites were plentiful.

An early Bowles ejection transfer trailer. An auxiliary engine powered a drum winch, which operated the ejector plate

This unusual side-dump trailer may have been specially built for a municipality

|

Bowles Transfer Stations

Bowles was a pioneer builder of transfer stations, having completed the first such installation in 1959. These saved money by consolidating the loads of several small packer trucks into a large trailer for transport to a distant disposal area. One such station was built for the City of Santa Monica in 1961, which closed their incinerator and began to dump city refuse at the Mission Canyon landfill, ten miles away in Los Angeles County.

The station consisted of a Bowles built pit-mounted refuse packer, which was fed from a staging floor where the city's Leach Packmasters would discharge their loads. Wheel loaders would then feed refuse from the floor into the hopper of the stationary packer. The sliding packer ram was 6' wide and by 3' tall, exerting 90,000 pounds of pressure and incorporated a follower plate for continuous loading capability. Power to the hydraulic pump came by way of a 60 H.P. engine, and the device could complete three packing cycles per minute.

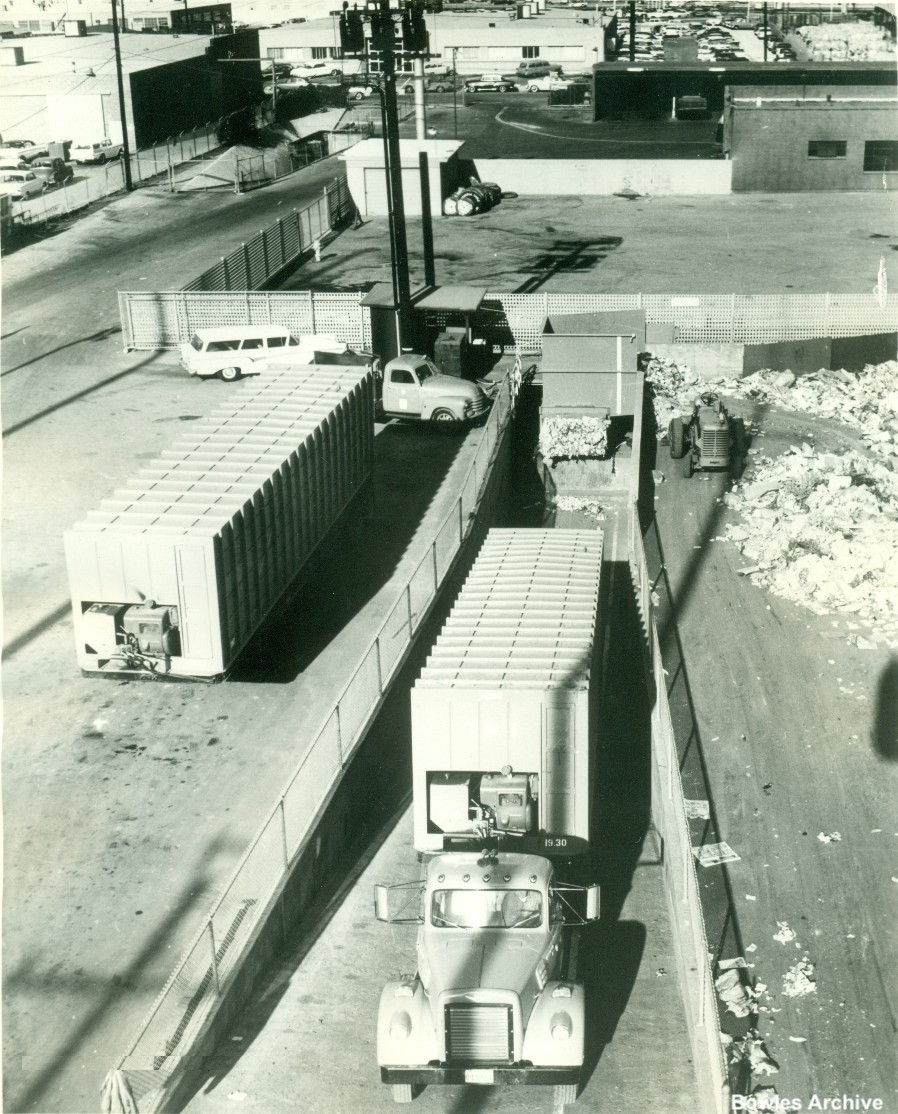

The packer discharged the refuse into one of three 58-cubic yard Bowles trailers. One trailer was backed down a ramp to the discharge opening of the packer, and secured to the structure by heavy chains. The ejector plate within the trailer was pushed from rear to front during the loading process, creating high-density loads.

Loaded trailer leaves the pit at the Bowles-built Santa Monica transfer station, while an empty one waits above

Once full, the trailer was hauled to Mission Canyon, while another empty trailer was moved in to replace it. Collection crews spent more time on the route, and less time on the road. As one trailer was being loaded, another one completed the round trip to Mission Canyon. For an initial investment of about $125,000.00, the City expected to save about $5,000.00 per month on refuse collection and disposal. The cost per ton to dump at Mission Canyon, including transportation and tipping fees, was about one half of what it had cost to dispose of trash in the city incinerator.

Scenarios like the one in Santa Monica would play out across the country during the coming decades, and transfer stations were to become an integral part of the refuse collection industry. Multiple-bay regional stations, both municipally owned and private, are found in almost every part of the industrialized world today.

|

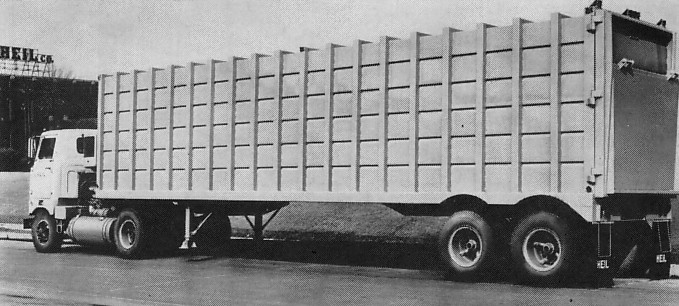

The old winch and cable ejector eventually was replaced by a hydraulic push out version as seen here

The telescopic ram was better suited to tremendous work of unloading these giant trailers. An optional air-cooled, V-4 Wisconsin gasoline engine could be mounted just ahead of the rear wheels, providing independent power for the ejector hydraulics. This allowed the use of a standard type truck tractor, without the need for a power take-off or hydraulic plumbing to connect to the trailer.

The Bowles transfer system found its way east, by way of an agreement with The Heil Co., of Milwaukee, Wisconsin,

which began advertising the system beginning in 1968. Shown here is a 75 cubic yard trailer.

|

1/17/10

© 2010

All Rights Reserved

Logos shown are the trademarks of respective manufacturers

Photos from factory brochures/trade advertisements except as noted

|

| |