Colecto

Municipal Sanitation Corporation

Bridgeport, Connecticut

HYDRAULIC COLECTO: REAR LOADERS (SECOND GENERATION)

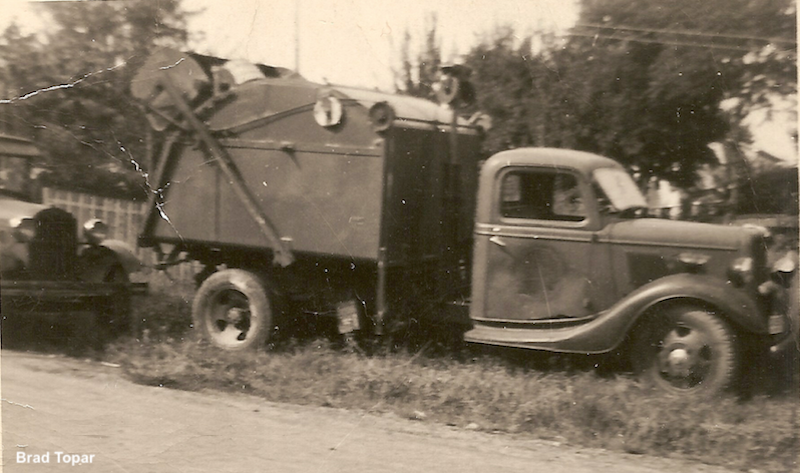

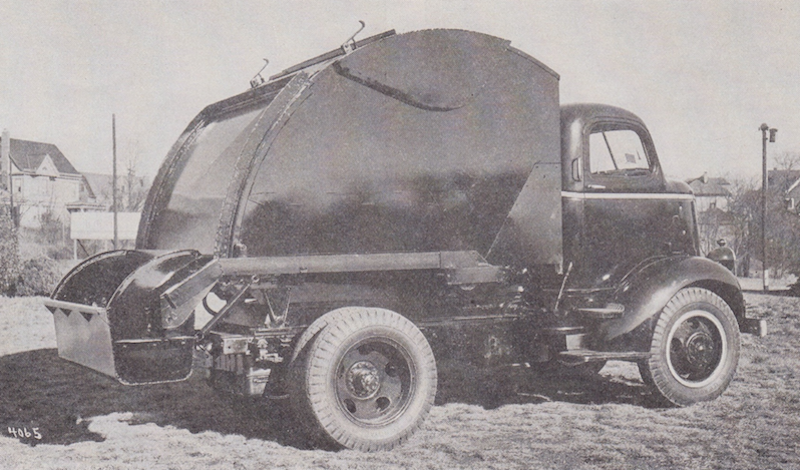

Hydraulic Colecto rear loader with bucket lowered, ready for loading at street level

With Elgin Sales now out of the picture, B. Nicoll resumed sales responsibility for Colecto, which now faced competition from the new Leach Refuse Getter rear bucket loader. This may account for the sudden engineering effort to improve the original chain-drive Colecto rear loader. In 1932, William Howard completely revised both the Colecto rear and side loaders, switching to hydraulic power for all loading and dumping functions. A single, vertically mounted hoist was used to raise and lower the bucket, via cables, as well as hoisting the body to unload. On the rear loader, an ingenious interlock system automatically secured the body from tilting while the bucket lift arms were in motion, and prevented the lift arms from moving while body was tilted. Operation of the lift arms was accomplished by connecting them by cables to the truck chassis. The hydraulic hoist was raised against a sheave arrangement, drawing the cables in and doubling the range of its effective stroke. This "reeving" hoist arrangement is today commonly used for roof-mounted container lifts on rear loaders, and in some roll-off hoists. Since elevating the lift arms left the hoist piston rod exposed above the roofline, a double-arm and latch system enabled the bucket to lock in the raised position while the hoist ram was lowered. Thus, the truck could be driven with the bucket raised without danger of striking the hoist on overhead objects.

A pair of hydraulic Colectos for New Bedford, Massachusetts, shown with their buckets in transport-lock position

Note how the inner (short) arms have lowered fully, while the outer (long) arms are locked in the raised position

To empty the body, the loader arms were switched to the raised-locked position, which elevated the bucket clear of the rear body door. The body was unlocked from the chassis, causing the continued movement of the reeving hoist to raise the front of the body, pivoting it on its rear hinges and dumping the load. The system looks more complex than it actually is, and was a great improvement over the original models. It was clearly less expensive to build, and used a single power source (the hydraulic hoist) to perform all operations. There were still mechanical elements (cables and sheaves), but far fewer moving parts than on the earlier versions.

A hydraulic Colecto, parked with the arms in the power raise position. Note how the inner and outer lift arms are

parallel to each other, and the hoist piston rod is extended above the roof line

HYDRAULIC COLECTO: SIDE LOADERS (THIRD GENERATION)

Patented concurrently with the rear loader in 1932 was a re-engineering of the original full-length bucket side loader. This would be the third and final version of the Colecto side loader. As with the rear loader, a vertical hydraulic hoist and reeving cable system was used for all loading and dumping operations. This hoist was used to turn a shaft atop the body, to which the bucket lift cables were attached. To return the bucket to ground level, the operator merely shifted the hydraulic valve, causing the lift ram to retract, and the bucket to descend by gravity. The bucket could be locked at the top for transport, by means of an operator-controlled latch, while springs assisted the piston of the lift cylinder to retract. The stroke of the lift cylinder was limited so that at no time could it extend higher than the top of the body, which protected it from damage. Incidentally, the SH bodies are known to have been fitted with Wood hydraulic hoists, which would indicate independence from Heil during this period.

The all-new Colecto SH-series side loader

To empty, the body was unlocked from the chassis, and the hoist lift cable was attached manually to a hook underneath the front of the body. The hoist then lifted the front of the body to dump the load. The new side loaders were designated model "SH", while Colecto rear loaders became model "RH". These improvements made to Colecto were significant, and the company was virtually alone in the market for self-loading refuse bodies in 1932. Their closest rival was the Refuse Getter, Leach's first entry into the refuse body field, which had only been introduced the same year. The strength of Colecto remained in the Northeast, where the urban population of the United States was highly concentrated. Municipalities seem to have been their biggest customers.

NEW OWNERSHIP: THE MUNICIPAL YEARS

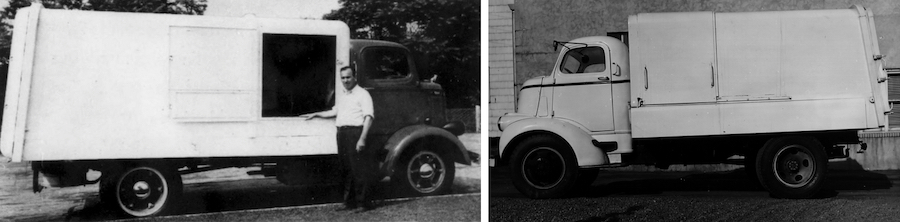

In 1933 it was announced that John E. Doran had resigned his position and Vice-President of sales at B. Nicoll & Company, to take the helm as President of the newly-formed Municipal Sanitation Corporation. The company was based at Bridgeport, Connecticut and would thereafter be the exclusive manufacturer and sales agent agent for the Colecto line of refuse bodies and catch-basin cleaners. Doran had been with Nicoll for over a decade, and was responsible for the introduction of the original side loader in 1928. Under his leadership, the company would continue streamlining their existing product, and introduce new body types, some of which were patented by Doran himself. Eventually, Colecto would become merely one model (a rear loader) in the Municipal family of refuse collection equipment.

Utica, New York took delivery of this Diamond T wit a Municipal 10-SH body in 1935

Colecto SH working on a snow-covered road in Bridgeport, Connecticut

HYDRAULIC COLECTO REAR LOADER (THIRD GENERATION)

Third generation Colecto 8 RH (8-cubic yard) rear loader from 1937, with direct-acting underbody lift cylinders

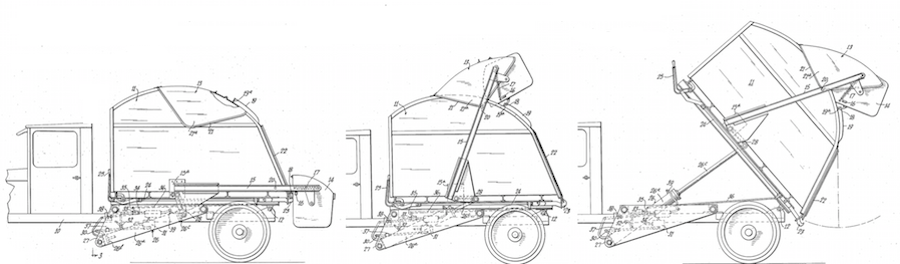

The first change under Municipal was a completely revised version of the RH rear loader. It arrived around 1935, now with lift arms powered directly by an underbody hoist. This was their cleanest design yet; good looking and well-engineered once again by William Howard. A pair of long-stroke hydraulic cylinders, mounted underneath the front of the body, operated the bucket and also tilted the body to unload. All of the cables, pulleys and hooks of the previous model were eliminated. In loading mode, a hydraulic oil bypass valve was manually opened, which limited the stroke of the cylinder to the relatively short distance needed to raise and lower the lift arms. In hoisting mode, The body was unlocked from the chassis and the bypass valve was closed. Thus, operating the hoist raised the bucket to the top of the body, and continued pushing the body up to discharge the load out the rear door.

The 1935 Colecto RH was a significant development in the history of refuse trucks, featuring the first known use of pivoting lift arms operated directly by hydraulic cylinders. This principle would eventually be applied to shovel-type truck loaders, and then to front loading refuse bodies when they first appeared in the early 1950s. Technically, Colecto was the leader in its field, with a cleaner design and fewer moving parts than the Leach Refuse Getter. In comaparison, the Leach had a far more complex mechanism, with rack-and-pinion gears driving a roller chain bucket lift. Though lacking compaction means, the 1935 Colecto RH was technically America's first all-hydraulic powered refuse collection body.

Third generation Colecto RH cycle: hoist cylinders operate bucket, and tilt body to unload

Third generation Colecto 6 RH rear loader on an International Harvester cabover

Clean-looking lines define this Colecto 8 RH rear loader

THE MUNICIPAL MODEL 'D' AUGER COMPACTOR

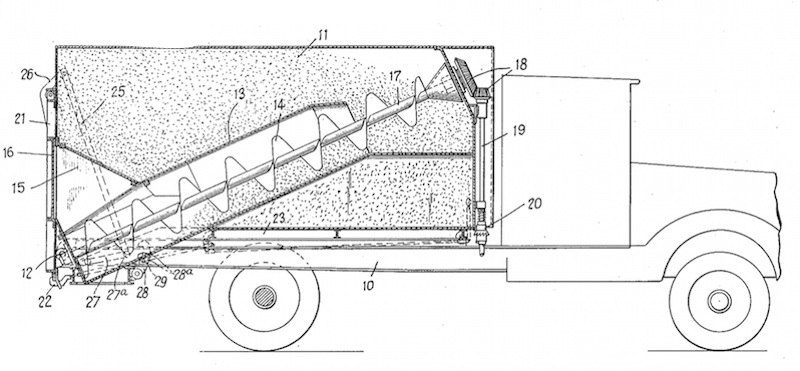

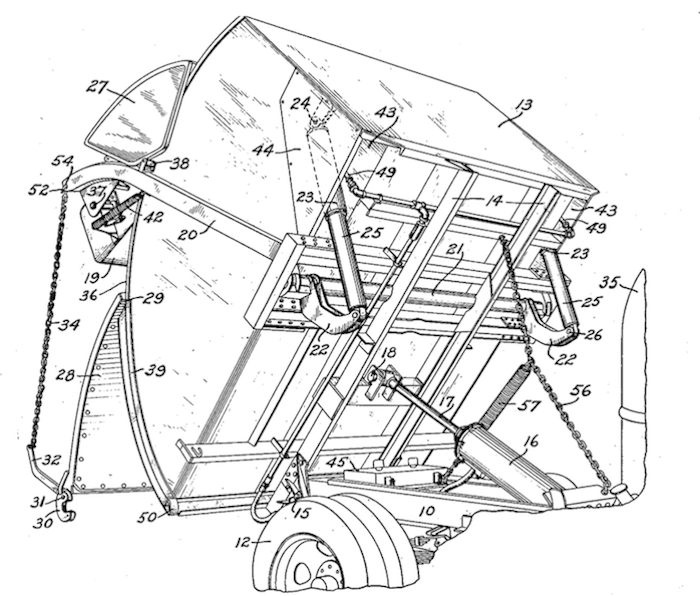

The Municipal Auger: Bevel gears (18) drive inclined auger shaft which loads and compresses refuse

Later in 1935, John Doran fielded his own design for a compaction rear loader, the first ever for Municipal Sanitation Corporation. This body was sold Municipal Model 'D', which probably stood for "Doran", and was a variation of a German design pioneered by Krupp around 1920. It consisted of an enclosed 12-cubic yard body with a small rear-loading hopper. An inclined screw, powered by the vehicle driveline, carried refuse from the hopper opening to the top of the body, depositing it therein. When the body became filled, compaction would occur as the screw pressed the refuse progressively. The screw was also effective at shredding, as refuse was forced through the twists of the auger. The Municipal Model D is notable as the first body built by Municipal that was designed by someone other than William Howard. A small number were known to have been supplied to the City of Philadelphia.

By the late thirties, the refuse body field was becoming increasingly crowded. In addition to Leach, Gar Wood and Heil were now directly entering the market, with the former introducing the fully-hydraulic Load-Packer bodies, and Heil adding a conveyor loader. Even smaller companies like Marion Metal Products were beginning to join the competition. The New York City Sanitation Department (DSNY) had adopted a refuse loader of their own design in 1937, and was contracting for hundreds of these escalator-loader bodies to be built by Gar Wood and Heil through the early 1940s. With the DSNY committed to their escalator-loader, it effectively ended any chance that Municipal would ever land a large order from the department, and may have spelled their ultimate doom.

Municipal Model D auger: Philadelphia was the only known user

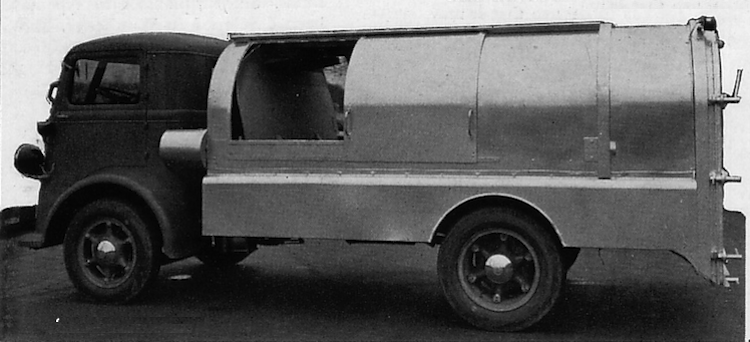

THE MUNICIPAL KOMPAKA HYDRAULIC SIDE LOADER

In 1940, Municipal fielded a completely new side loader called Kompaka. It was a tank-shaped structure loaded through doors on both sides at the front to the body. A hydraulic-powered packer plate compressed the load towards the back of the body, and also ejected the load without tipping at the disposal site. The Kompaka was based on the concept of the Marion Compressor, which had used worm gears to mechanically drive the packer plate. Municipal's new side loader was another major innovation, and although the inventor is not known at this time, it may have been Municipal's president, John Doran.

In 1940, Municipal fielded a completely new side loader called Kompaka. It was a tank-shaped structure loaded through doors on both sides at the front to the body. A hydraulic-powered packer plate compressed the load towards the back of the body, and also ejected the load without tipping at the disposal site. The Kompaka was based on the concept of the Marion Compressor, which had used worm gears to mechanically drive the packer plate. Municipal's new side loader was another major innovation, and although the inventor is not known at this time, it may have been Municipal's president, John Doran.

The Kompaka was another engineering triumph for Doran and Municipal, joining the Model 'D' auger and the Colecto in America's most diverse line of refuse collection equipment prior to the Second World war. This was no small feat, considering Municipal was not and established truck body or hoist manufacturer, as were Gar Wood and Heil. Doran had built the company from the ground up, starting with his days as sales manager for B. Nicoll and company in the 1920s.

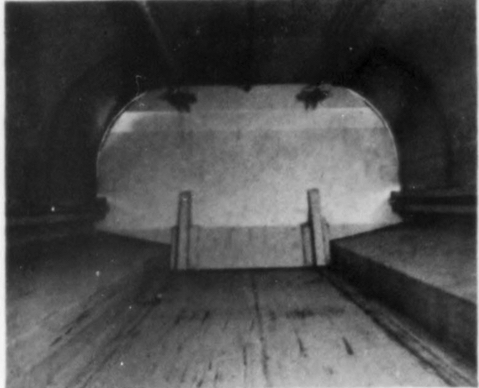

Inside-the-body view of the packer of the Municipal Kompaka

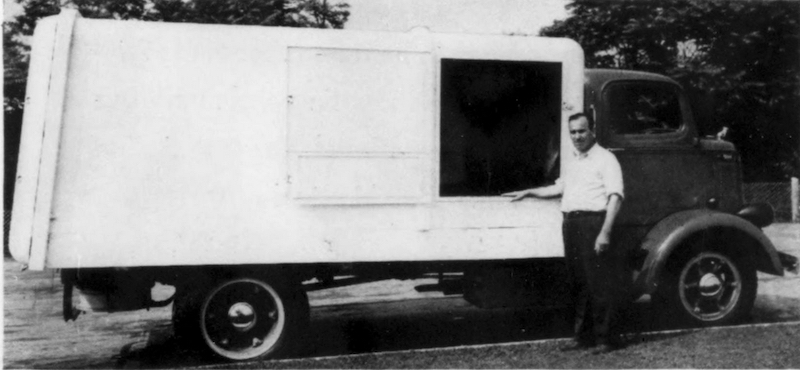

Municipal now fielded America's first full-eject hydraulic side loader, a compaction auger loader and the venerable Colecto bucket loader. Before 1940 was over, the Kompaka received a greatly enlarged and squared-off body with larger side loading doors, and the Colecto would also get another major update.

The improved 1940 Kompaka, with larger body. The man in the picture is believed to be Municipal's president, John E. Doran

HYDRAULIC COLECTO (FOURTH GENERATION)

With the introduction of the 1940 Colecto came the first signs of Municipal Sanitation Corporation's increasing involvement with The Heil Company. Paul Schutz and George Kuhlman patented the fourth-generation Colecto rear loader, assigning the rights to Heil. Kuhlman was at that time the Vice President of Heil, and manager of the Hillside, New Jersey factory. His involvement with this particular product may indicate an increasing importance placed on refuse bodies by Heil in the late 1930s. Colecto was still officially sold as a product of Municipal Sanitation Corporation through 1940.

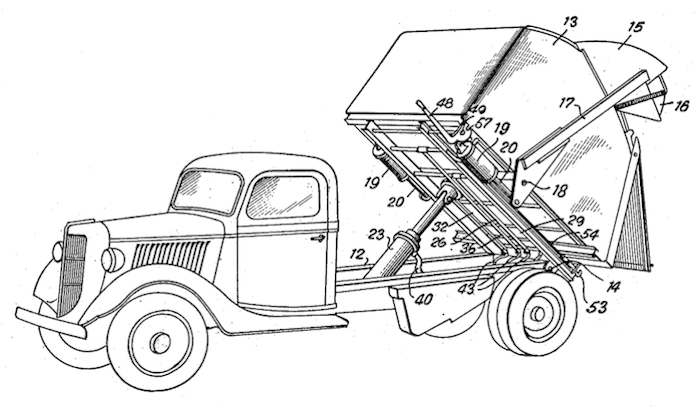

1940 Heil Colecto: Lift cylinders are mounted behind triangular plates at front of body

The improved 1940 Colecto used two single-acting lift cylinders, positioned vertically in pockets located inside the front corners of the body, to operated the lift arms. The arms were connected through a transverse rock shaft. The bucket was raised under power, but coasted back down under the weight of the bucket and arms. This principle became a staple of front loader design in the 1950s, and has been with the industry ever since. To unload, the rear door was unlatched and a set of chains were attached which connected the lift arms to the door. As the lift arms were raised, the door was pulled open automatically. A single underbody hoist raised the body to discharge the load.

A revised version of the Colecto rear loader had been drawn up by John Doran in 1939, but there is no evidence that it was ever built. Doran's design was very similar in principle to the 1940 Heil-designed version, with two small horizontally-mounted cylinders actuating the bucket lift arms. These were double-acting (powered in both directions), and pushed rearward against the lift arm brackets.

1940 Heil Colecto; single-acting lift cylinders (23) were mounted at front of body (24) and connected by a common shaft (21)

To open the rear door, a chain (34) was hooked to the door which was pulled clear as the lift arms raised

John Doran's 1939 version, with double-acting "pusher" cylinders (19); there is no evidence it was ever in production

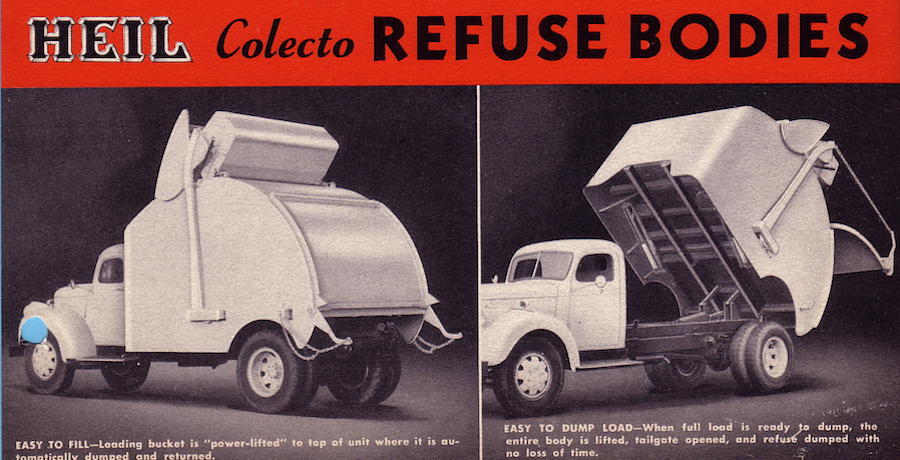

HEIL COLECTO (FIFTH GENERATION)

The final variant of the Colecto is believed to have made its debut around 1941-42, featuring a streamlined appearance and with bucket lift cylinders mounted horizontally, beneath the body. It was somewhat of an amalgamation of Doran's 1939 patent and that of Shutz and Kuhlmans 1940 Colecto. War production consumed most of America's production capacity between 1942-1945. This 5th generation variant that would appear in January of 1945 as the first Heil-branded Colecto.

Although no press release has yet been discovered, it is highly likely that John Doran sold the rights to the Colecto to Heil, and went out of business around 1941. Municipal Sanitation Corporation was probably too small to survive the upheaval of manufacturing in the United States once war had been declared on Japan and Germany. This would be most a most unfortunate turn of events for Doran, who was way ahead of his time in foreseeing the market for specialized refuse bodies. Municipal was just beginning to field some highly advanced models when hostilities broke out.

There remains another possible connection between Municipal Sanitation and the post-war refuse body industry. The 1940 Municipal Kompaka may have been "re-incarnated" as the Marion Hydropaka side loader. Very little is known about either model, including patent information. However the two products are functionally and visually very similar, and even their names have a familiar ring. The fact the the Marion Kompaka appeared right after Municipal folded may not be a coincidence.

Similarities between the 1940 Municipal Kompaka (left) and 1949 Marion Hydropaka (right) are striking

Both John Doran and William Howard must be considered important figures in the history of refuse collection equipment. In the midst of the Great Depression, Colecto was one of the first dedicated builders of refuse bodies in America, at a time when the horse and motor truck were still competing with each other. Howard and Doran's patents document a sustained commitment to improve their product, culminating in an impressive multi-model lineup by 1940. Only the outbreak of war may have prevented Municipal Sanitation Corporation from becoming a major force in the booming post-war market.

Along with ATIA, the Colecto side loader was one of America's first mass-marketed refuse trucks, and its most successful in those fledgeling years of the industry. The Colecto rear bucket loader design was widely imitated, and was undoubtedly an inspiration for the first front load refuse trucks of the 1950s. Modern-day rendering bodies can also trace their roots directly to Howard's 1929 design. Although the side-bucket loader mostly disappeared after 1939, it enjoyed a renaissance in the late 1980s, finding new life during the recycling boom as several firms introduced similar multi-compartment collection bodies for glass, metal and paper.

Colecto rear bucket loader emerged after WWII as a product of the Heil Company

PATENTS:

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US1922851 |

Self-Loading Dump Body (Colecto rear loader-hydraulic/cable) |

William S. Howard |

B. Nichol & Co. |

April 30, 1932 |

|

US2020245 |

Apparatus for Handling Material (Colecto side loader-hydraulic/cable) |

William S. Howard |

B. Nichol & Co. |

December 14, 1932 |

|

US2020246 |

Apparatus for Handling Material (Colecto side loader-hydraulic/cable) |

William S. Howard |

B. Nichol & Co. |

November 15, 1934 |

|

US2101067 |

Material Handling Apparatus (Colecto rear loader-hydraulic) |

William S. Howard |

B. Nichol & Co. |

October 22, 1935 |

|

US2110207 |

Self-Loading Vehicle (Municipal auger) |

John E. Doran |

|

October 22, 1935 |

|

US2231058 |

Material Handling Apparatus (Municipal rear loader-hydraulic) |

John E. Doran |

|

May 26, 1939 |

|

US2271444 |

Self-Loading Vehicle (Heil Colecto rear loader-hydraulic) |

Schutz, et al |

Heil Co. |

July 19, 1940 |

REFERENCES

American City Magazine: 181. High Speed Refuse Collection

November 1932, page 22

American City Magazine: Doran Becomes President of Municipal Sanitation Corporation

January 1933, page 99

American City Magazine: New Rear Loading Body for Garbage-Ash Trucks

October 1935, page 103

American City Magazine: New Refuse Collection Body

February 1940, page 126

American City Magazine: Refuse Body Compacts Load of Bulk Rubbish

September 1940, page 127

|

7/2/16 (updated 5/11/24)

© 2016, 2021, 2024

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

| |