The Early Dumpmaster

Despite Dempster's advances in refuse handling systems during the 1950s, a much more efficient method of bulk collection was emerging, being in large part developed by west coast body builder S. Vincen Bowles. In conjunction with a southern California refuse contractor, Bowles had developed and sold a fixed-bucket front loader in 1952, and shortly thereafter had modified it to service detachable containers. Bowles' loader used flat forks to couple with individual containers, which were then hoisted skyward and dumped into a large open body. These new, efficient "front loaders" would be the wave of the future, especially as increasingly longer hauls were becoming common. Dempster didn't waste any time introducing their own front loader, but it was essentially a stop-gap solution that was a Dempster in name only.

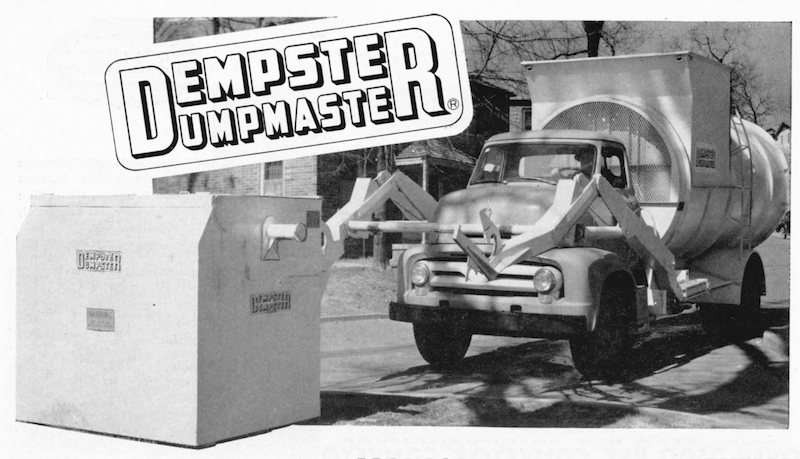

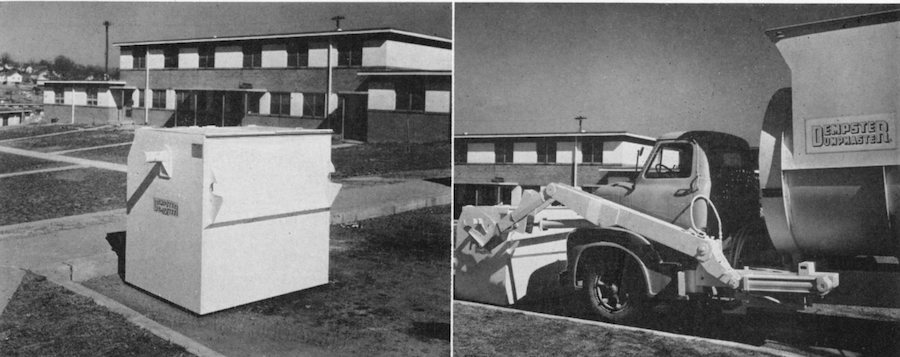

Beginning in 1955, the Dumpmaster front loader line was added to the Dempster family, establishing them in the growing field of manufacturers offering this style of body. The original Dumpmaster as shown above, was a departure from the old Dumpster system in that it was capable of emptying several containers before going to the disposal point, as opposed to the "one at at time" method of Dumpster System. A special new top loading, top dumping container was also developed, which was designed to be emptied by inverting over the top of the truck body. Though completely new for Dempster, this front loader was actually an amalgamation of two well established products: The Pak-Mor refuse packer body and the Holmes-Owen bucket loader. Ernest Holmes Company of Chattanooga had been offering variations of the loader as an attachment for standard dump trucks since the late 1930s. By the early 1950s, they were using a two piece "articulated" lift arm with the main lift cylinders under the frame, and a tilt cylinder at the mid point of each arm at the joint. They secured patents to the device shown above in 1955, which differs mainly from their shovel loaders in that two large "claws" take the place of a fixed shovel or bucket.

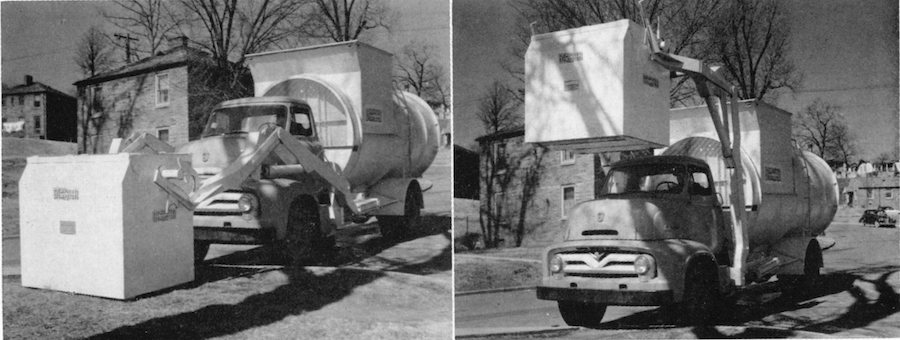

On approaching the container, the driver positions the claws at a level below the studs protruding from the sides of the container, and then advances the vehicle until the claws are just beneath the studs. Note the long ramp formed by the claw which helps guide the stud into the eccentric slots as the arms are raised. The main hoist arms are next raised which elevate the container above the cab, and then the tilt cylinders are energized which invert and empty the container over the top opening of the body. During the entire lift cycle, the container remains in place by gravity, held in place in the eccentric slots formed in the claw. A riser extension to the circular body helps channel the refuse and minimize wind-blown refuse. One interesting aspect of the Holmes-Owen articulated arm is that in the lowered position, the arm joint is not completely straight, allowing the arm assemblies to clear the truck fenders, and thus prevent interference with steering control, which was a problem on some early front loaders.

Unfortunately the new system was incompatible with the old bottom dumping Dumpster System in which so many cities had already heavily invested. In some cases, cities had encouraged, or compelled merchants to purchase Dumpster containers to be serviced by city-owned trucks. Sanitation departments could hardly pull the rug out from under such a system without a justifiable outcry from these business owners. There was really no way around this, since a front loader designed to service bottom-dump cans would have been needlessly complex. In this regard, Dempster was in somewhat of an unenviable position, since their new Dumpmaster front loader was in direct competition with their established and popular Dumpster System. West coast builders like Bowles were selling the front loader idea to communities that were often still employing manual collection with open body trucks! On the other hand, Dempster was virtually unchallenged in the portable container field and pretty much had the entire eastern market to themselves. Needless to say, the old Dumpster System was not discontinued, and this first Dumpmaster front loader was to be short-lived. Within two years, a completely new style of front loader would emerge, as well as a solution to the compatibility issue with bottom-dumping containers.

Pintle-type container, approach and hook-up

Dumpmaster lift arm could be fitted to any packer truck capable of top loading, such as Pak-Mor...

...or Packa-Van

This recently discovered photo shows an articulated-type lift arm mated to the Dempster-designed compaction body, which was used on the next generation of Dumpmasters. This interesting hybrid is either a very rare transitional model, or a one-off prototype. The photo was inset in a 1992 Dempster brochure.

The Dumpmaster is also noteworthy in that it was among the first front loaders to use a compaction type body, in this case the tried-and-true Pak-Mor with its chain drive packer plate. The compaction body front loader was a trend which all other makes would eventually follow in one form or another. Though Dempster didn't invent the front loader, and even relied on The Ernest Holmes Co. to develop their first model, the company would soon catapult to phenomenal success mostly on the shoulders of the next generation of front loaders.

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US2828032 |

Self Loading Cargo Vehicles |

Beasley, et al |

|

March 7, 1955 |

|

US2949199 |

Containers for self-Loading Vehicles |

Jones |

Dempster Bros. |

July 14, 1955 |

1/7/06

© 2006, 2013

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|

| |