Eagle Engineering

(Continued)

EAGLE CRUSHLOAD

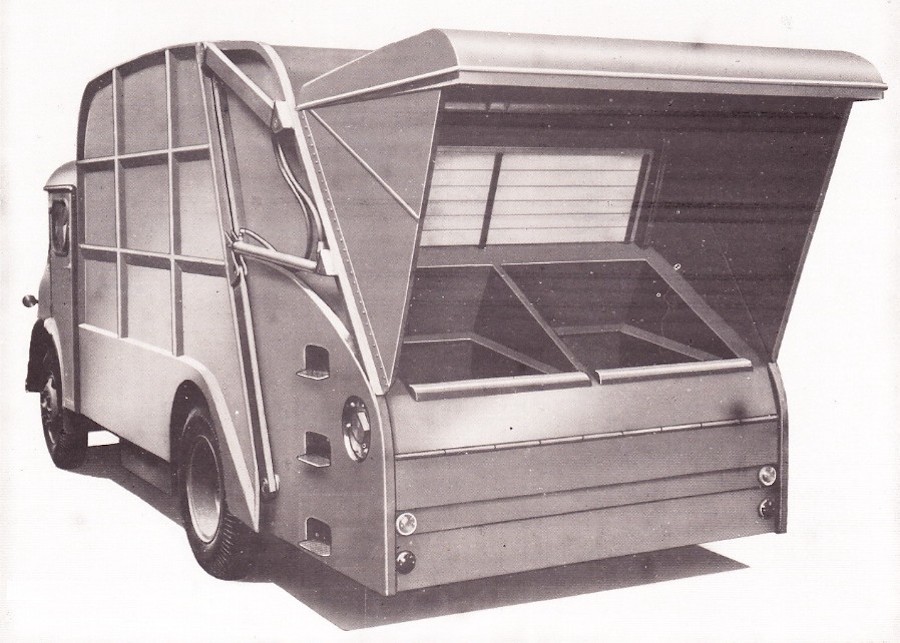

A all-new continuous-loading packer was introduced in 1962 called the Crushload. Using a complex, compound packer which pre-crushed the refuse, it appears to have been designed to compete with with the Dennis Paxit II and SD Pakamatic bodies. A somewhat conventional "inverted drawer" packer box first shoved the refuse directly against the back wall of the hopper, crushing it. Next, the hopper floor was elevated to expose the opening to the main body, into which the charge was shoved into the body by continued extension of the packer drawer.

As beneficial as pre-crushing can be, with a claimed reduction of 3:1, it was overly complex by comparison with contemporary rivals. It was constructed of reinforced COR-TEN steel for corrosion resistance and strength, due to the high stresses encountered by pre-crushing. Crushload marked the beginning of rough times for Eagle, and was very quickly re-designed.

EAGLE CRUSHLOAD Mk II and Mk III

Eagle Crushload MK II

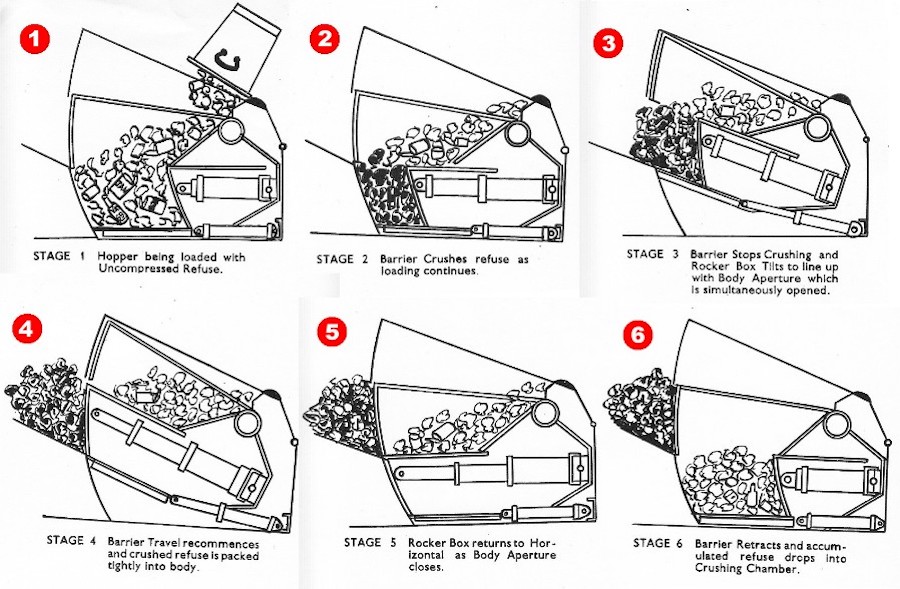

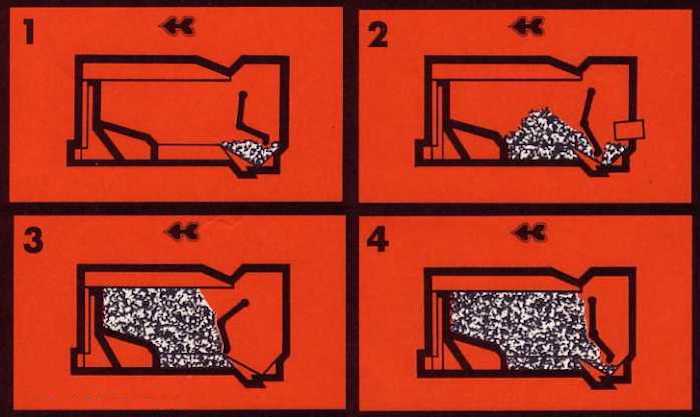

A somewhat simplified Crushload Mark II in 35 and 50 cubic yard sizes arrived for 1964, with interconnected crusher and injector panels. Loading remained continuous. Each charge was first crushed against the top of the "inverted drawer" packer, fell down in front of the packer face and was then "injected" into the body. In 1965, The 75 cubic yard Mark III was introduced on a Seddon tandem axle chassis. The Mark III body sloped up at the front for optimal counterbalancing at the tip. This revised Crushload soldiered on a few years before yet another complex and oddly-engineered rear loader would emerge from Warwick.

Crushload Mk II pre-crushing and packing action

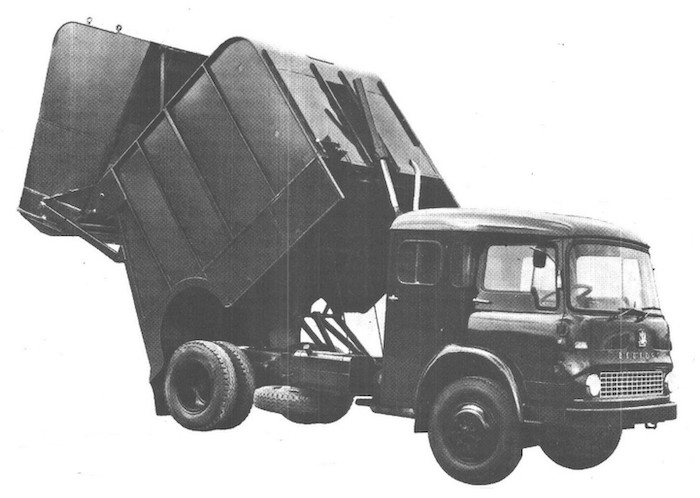

Rear view of some Eagle Mk III bodies

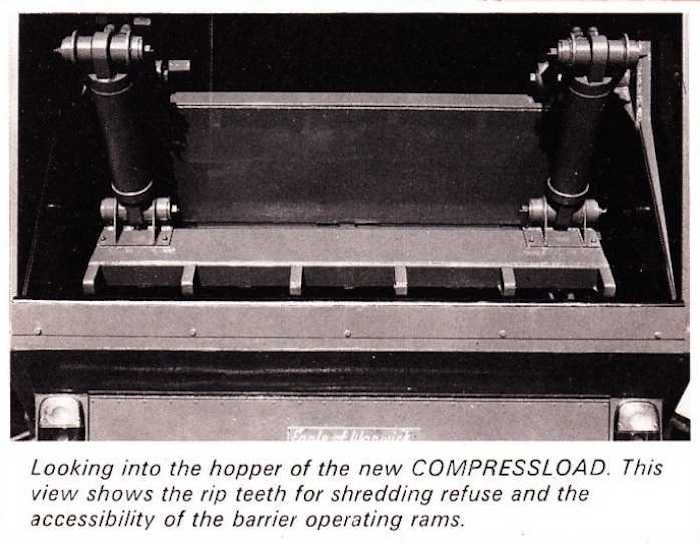

COMPRESSLOAD

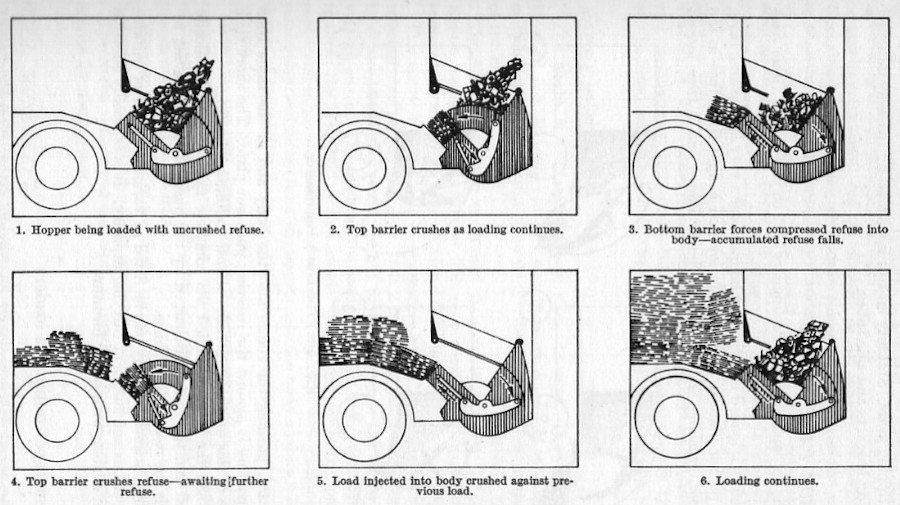

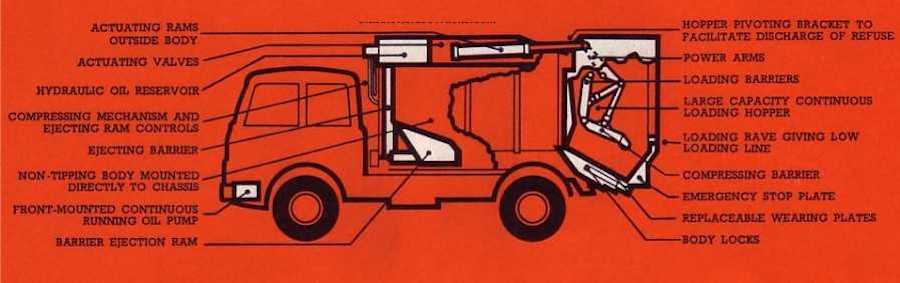

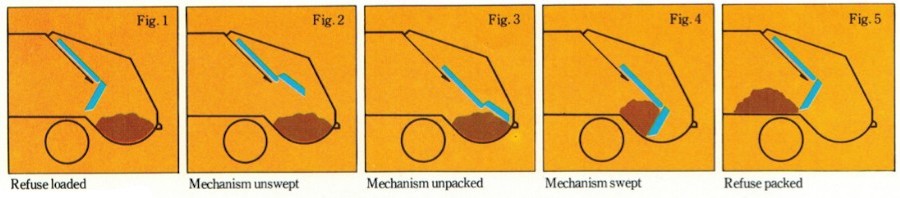

1967 saw the next new Eagle design emerge, in the form of the radical Compressload, a heavy-duty packer with two hinged panels operated by roof-mounted hydraulic cylinders. It was a continuous loader, designed to consume small batches of refuse under high pressure. Thus, smaller bodies were offered, in comparison to the Crushload. Discharge was by hydraulic ejection, a feature not seen on an Eagle body since the 1940s Compressmore.

Schematic of the packer system. Roof-mounted rams doubled as tailgate lifts

Lower panel pre-crushes load against floor, the upper panel drags load into body

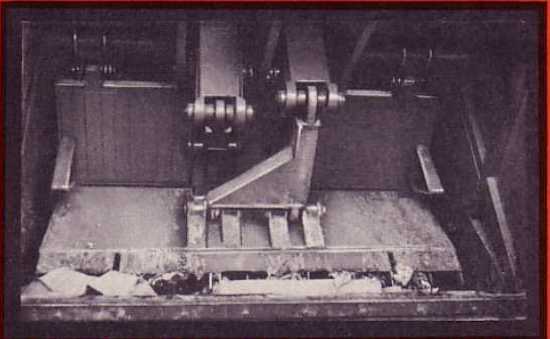

This view shows the mechanical linkage connecting the roof-mounted rams to each individual panel

Shredder teeth on lower panel assist in devouring sacks and other bulky waste

COMPRESSLOAD-1970s VERSION

The late 1960s marked a period of instability for Eagle, with company going through several changes of ownership. In 1972, Hestair Engineering finally took control of Eagle. In a significant development with future ramifications, Hestair also took control of Dennis Brothers about the same time. Revisions were made to the Compressload, which received twin direct-thrust rams for the lower crushing panel, and larger volume bodies.

Compressload ejection barrier

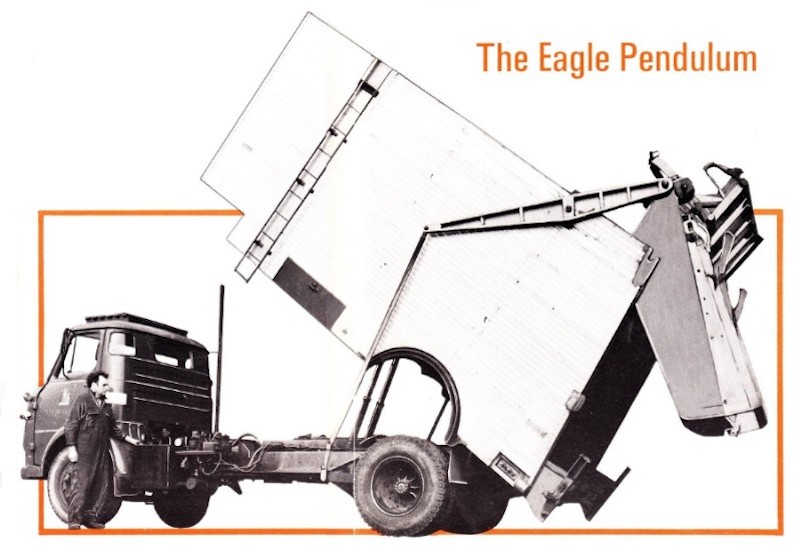

Under the Hestair ownership, Eagle took over sales of the Pendulum, a swinging-gate type of packer originally produced by John Gibson & Sons Ltd. of Edinburgh, Scotland, which had gone bankrupt in 1971.

EAGLE PAK-MOR

Eagle also sold the American Pak-Mor H-Series circular side load packers during the 1970s

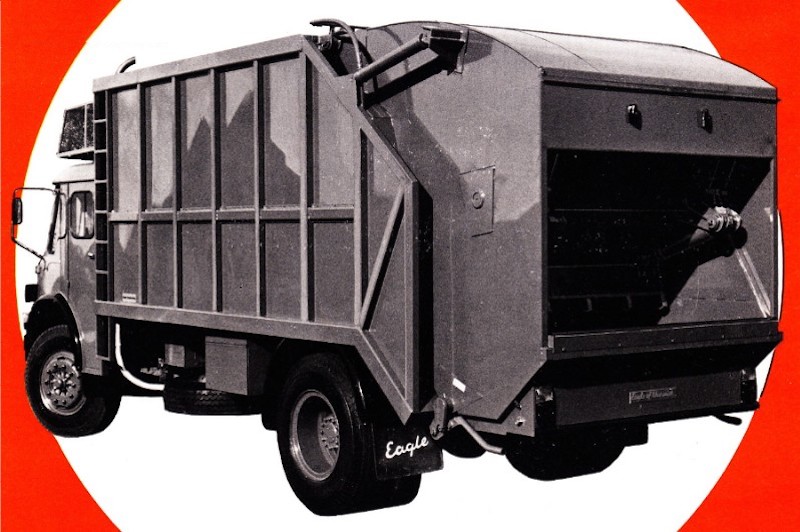

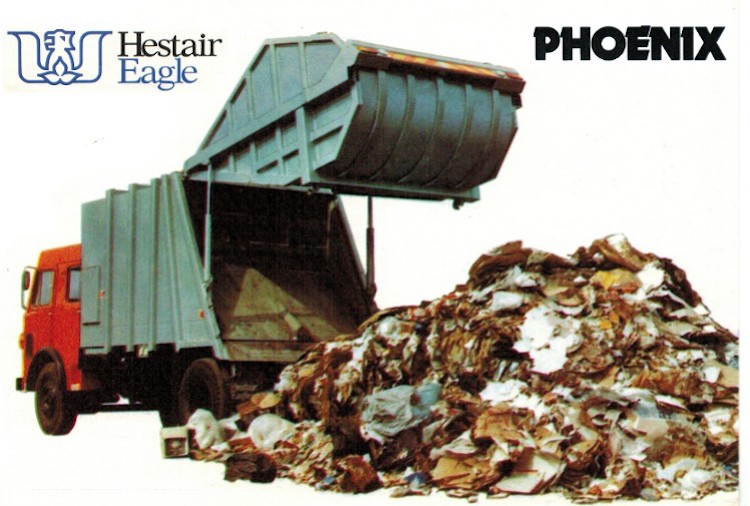

HESTAIR EAGLE PHOENIX

A two-year engineering program came to fruition in the spring of 1978 with the announcement of the Phoenix, an all-new rear loader. This was England's first domestically designed and built slide-sweep style intermittent loader, and would at last return Eagle to its former glory. A generous low loading hopper of 2.1 cubic meters, and ejection-discharge instantly brought the brand up to date. In 1985, Hestair would combine the Eagle Phoenix body with the Dennis truck chassis and sell complete refuse vehicles under the Dennis Eagle brand, which continues to this day.

The Phoenix was originally sold in Australia under the Fruehauf name (now Dennis Eagle Australia). In Canada, Phoenix bodies were built by Jaeger and were sold in that country as well as the United States, but are no longer in production.

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

GB953142 |

Improvements Relating to Refuse Collecting Vehicles |

Palmer, et.al. |

Eagle |

December 2, 1961 |

|

GB1058594 |

Improvements relating to Refuse Vehicles |

Palmer, et.al |

Eagle |

June 4, 1963 |

|

GB1119194 |

Improvements Relating to Refuse Collecting Vehicles |

Merther |

Eagle |

April 23, 1966 |

|

US4273497A |

Refuse Storage and Discharge Apparatus |

Mealing, et.al. |

Hestair Eagle |

June 26, 1978 |

© 2015

All Rights Reserved

Logos shown are the trademarks of respective manufacturers

Photos from factory brochures/trade advertisements except as noted

|

|

| |