Ebeling Manufacturing Company (EMCO)

Plainview, Texas

by Eric Voytko

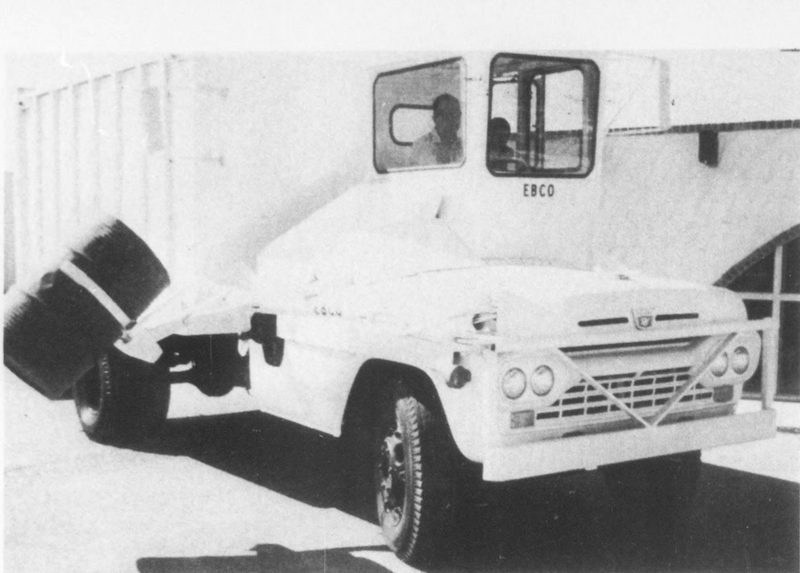

An early ASL built by the Ebeling brothers circa 1972, badged as an "EBCO"

The pioneering work of the city of Scottsdale, Arizona in the creation of automated collection systems is well documented, but it was a small Texas company that really broke open the market in the 1970s. What would ultimately become Ebeling Manufacturing Co. (EMCO) of Plainview, Texas, can trace its beginnings back to 1969, the same year Scottsdale initiated the original "Godzilla" automated side loader project. Brothers Ernest and Franklin Ebeling began with a simple lift that would dump 55-gallon drums, a common refuse container in those days, and an extremely heavy one at that. The brothers sought to prefect a system that was fully automated, where the driver never had to leave the cab. Some municipalities were then using the Pak-Mor Handi-Lift system for residential alley collection, but this required the driver to manually attach cables to wheeled metal containers. The Ebelings came up with a design that would handle the larger containers, being engineered for side-loading packer bodies, because alley collection made rear loaders unsuitable for those areas.

Introduced in 1961, the Pak-Mor Handi-Lift system was popular in many Texas cities. It required driver to exit cab and attach cables

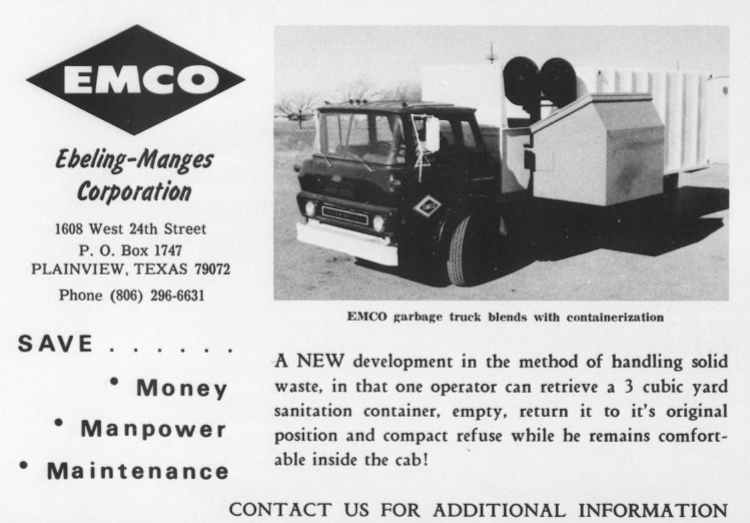

The future of refuse collection had arrived in 1973, as EMCO was officially launched, becoming the first to market a turn-key automated refuse collection system. Special 3-yard containers, built by EMCO, were suitable for residential or commercial collection. A rectangular partial-packer type side loading body was the foundation, with a patented chain-type EMCO lift which would "reach out" and grab the container, lift and empty it, and return it to to the street while the driver remained safely inside the truck. The first sale went to the city of Idalou, Texas, but delivery had to be delayed because it was the only unit available for promotion.

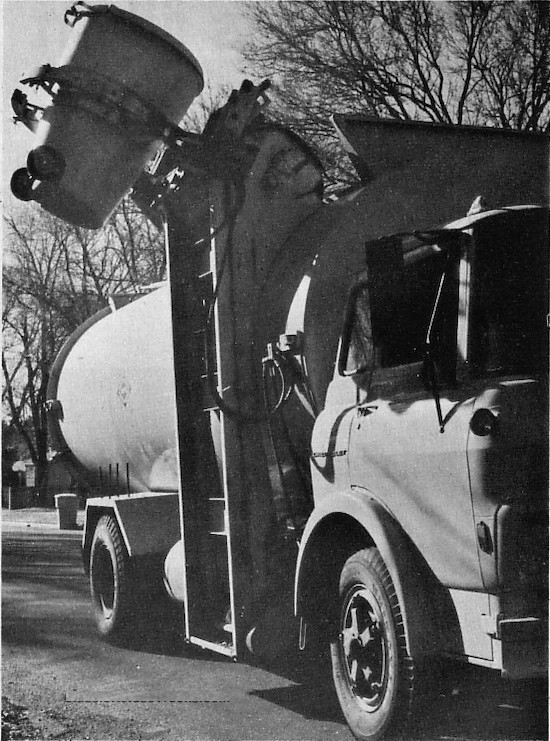

The EMCO lift was a fairly simple device, consisting of a telescoping carriage with rail-guided roller chains driven by a hydraulic motor. Attached to the chains was a lift bar which engaged hooks made into the containers. Energizing the motor caused the chains to elevate the lift bar until it reached the top, rolling over the upper sprockets and inverting the container over the hopper. The motor was reversed to return the container to ground level. The entire carriage was mounted on a slide, powered by a hydraulic cylinder, allowing it to extend outward to "reach" containers a distance from the truck. The mechanism was controlled by a cab control using electro-hydraulic solenoid valves and limit switches. The lift could be mounted to either side of the body.

1973: Ebeling-Manges Corporation introduces the industry's first mass-marketed automated side loader (ASL)

Guy Manges was one of the officers of the early corporation. Later, it became simply Ebeling Manufatcuring

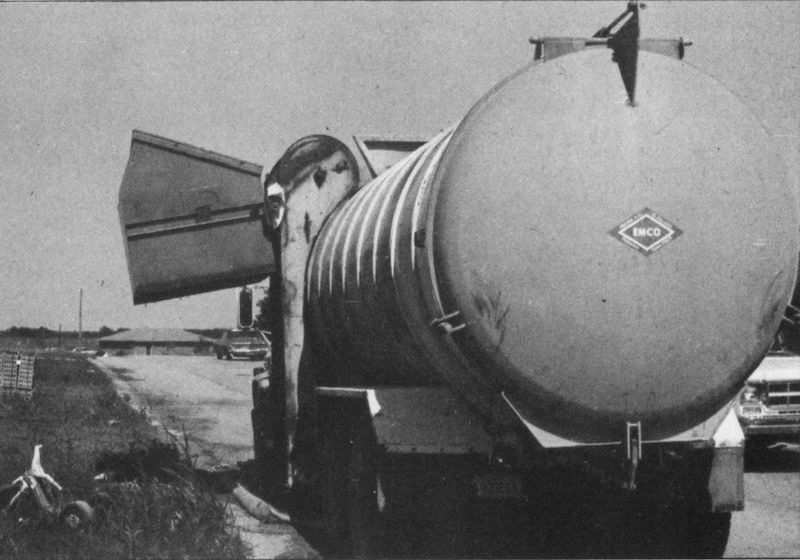

In 1974, the company introduced a modern, circular 28-cubic yard body to go with their advanced new loading system. It featured a two-stage packing ram of immense length, protruding several feet in front of the packer panel face. Because of this, the packer plate could not travel the full distance of the body without contacting the tailgate. It functioned as a partial-packer during the loading operation, clearing the hopper area and compacting the load as the body became filled. At the dumpsite, the hopper door was raised hydraulically, and the panel was extended the full length of the body to eject the load. (See the next chapter for details on the packer/ejector blade)

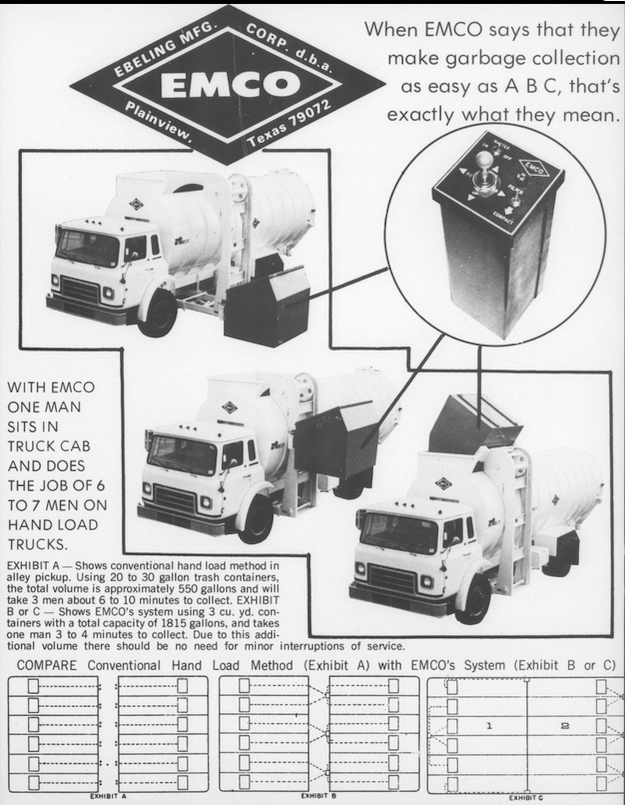

1974 advertisement showing the new circular compaction body

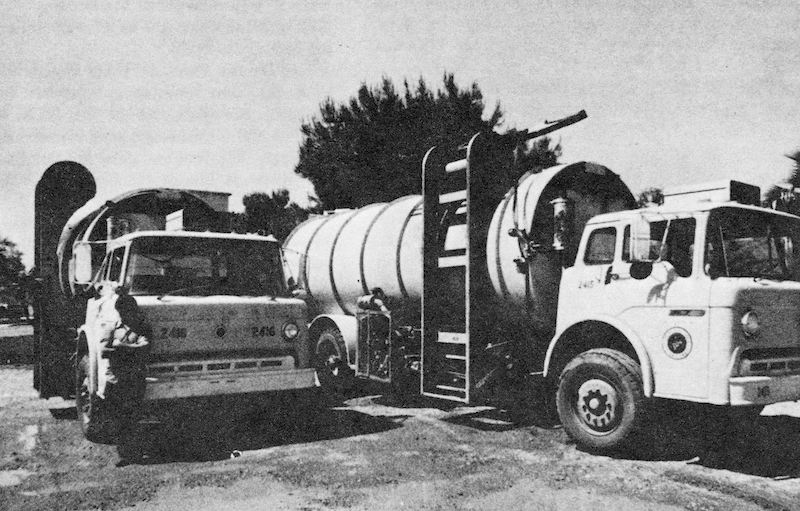

As the EMCO had one of the few commercially available rail lifts available during the mid-seventies, it was sometimes modified with 'grabbers' to lift the 90/300-gallon round plastic containers which were used in some cities. Modified or not, the EMCO lift could be fitted to most any side loader on the market. This was the case in Scottsdale, when that city ceased building their own custom-made ASL refuse trucks. A pair of Pak-Mor barrel trucks with EMCO hoists were purchased in 1977, and modified with gripper arms made by Government Innovators Inc., the company formed by Marc Stragier which would later be known as Rapid Rail. This kind of 'cross-breeding' of equipment was not uncommon in the early years of automated collection.

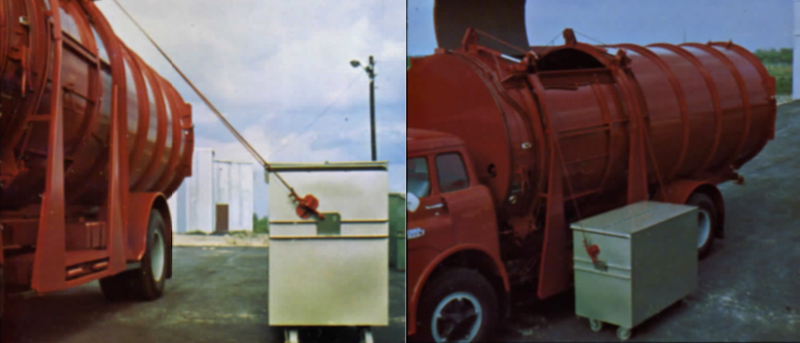

Scottsdale's cross-breeds: Pak-Mor body, EMCO lift and Government Innovators (Rapid Rail) cart gripper.

These were purchased in 1977 to replace two worn-out "Son of Godzilla" ASLs

EMCO in action:boom extends horizontally away from truck to engage container

Chain hoist raises container off of ground, retracts horizontally towards truck

Chain hoist lifts can, which is inverted as it follows curve of tracks towards the top

1976 advertisement showing the efficiency of the EMCO system

Rear view of EMCO body, showing automatic tailgate locks (below) and tailgate cylinder mounted to roof

By 1977, the EMCO packer body was streamlined, eliminating the most of the reinforcing ribs.

This rig was custom-fitted with a Rapid Rail gripper for plastic carts in Sydney, Nebraska.

12/08/24

© 2024

All Rights Reserved

Logos shown are the trademarks of respective manufacturers

Photos from factory brochures/trade advertisements except as noted

|

| |