EMCO (continued)

The Automation Explosion

In the late 1970s, EMCO was the biggest producer of automated systems in the world, although this must be kept in perspective since there were only a handful of communities using any kind of mechanized collection. Competing with EMCO were Government Innovators (Rapid Rail) and Litter Lift, both of which manufactured lifts for use on 90/300-gallon molded plastic containers. By contrast, the EMCO system used a much larger 3-yard steel container for multi-family use, primarily in alley collection routes. Thus, EMCO was a particularly attractive system for large urban sanitation departments because of the scale of the systems. Cost savings could be realized rapidly and service greatly improved over traditional collection methods. For EMCO, these large-scale operations meant large-scale purchases.

Automated collection was making its way out of the "Sun Belt" cities of the southwestern United States. By 1979, St. Louis, Missouri became the first major city to begin using the EMCO system, culminating in a 1981 order for fifty trucks and 23,000 containers. That same year, Detroit also adopted EMCO for alley collection routes and made another major purchase. To keep up with this demand, container manufacturing was augmented by contractors in Nebraska and Arizona. Back in Plainview, the factory was expanded and added a second shift.

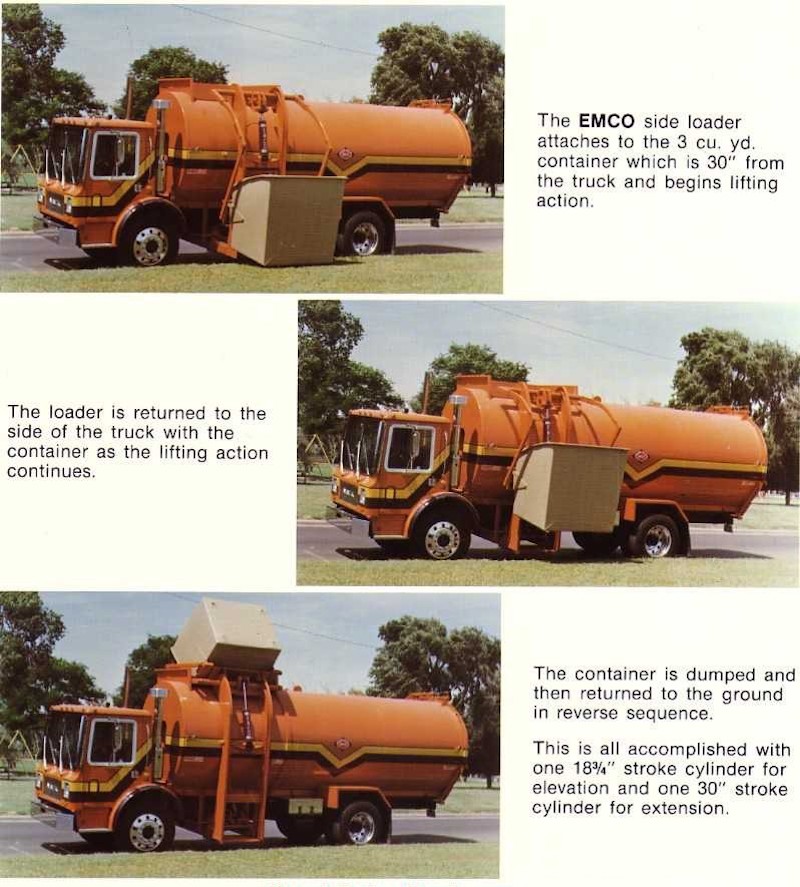

Another advantage leading to the early success of the company was a motivated sales force, and the fact that EMCO offered a route-ready system. They provided the packers, lifts and containers in one contract, along with employee training and route design. The alleviated customer concerns of equipment compatibility, with EMCO handling any issues that may arise. At that time, systems like Litter Lift and Rapid-Rail were "hybrids", being adapted to standard side loaders such as Shu-Pak, Hydepak and Pak-Mor. Nevertheless, EMCO trucks and equipment were modified for use in some communities that used the 90-gallon molded plastic carts. The Rapid-Rail cart gripper was often adapted to EMCO units, including in markets as far off as Australia.

Despite their successes in automated collection, EMCO was essentially uncompetitive in one important market segment. Their lift was not compatible with the molded plastic "wheelie" carts as used with automated single-home collections. In an attempt to make their system work in the suburbs, EMCO added an 82-gallon wheeled container designed by Pawnee Plastics Inc. (PPI). These were basically low, semi-auto type carts typically used with rear loaders, and required much more precise alignment to be 'hooked' by the EMCO bar-type lift. Very few of these appear to have been sold, while the competitive gripper-type arms for round plastic cans became the industry standard.

EMCO partnered with PPI to offer cart collection, shown here emptying two 82-gallon wheeled carts

Meanwhile, the new EMCO packer body, now a smooth-sided tank-like structure, standardized on three sizes of 20, 25 or 30-cubic yards capacity. In early 1980, the original chain-rail system was replaced by and all-new linkage type lift. It used a single hydraulic cylinder for all lifting and dumping functions. Another long-stroke cylinder operated the retractable carriage. In addition to increased capacity, it eliminated the chains, cables, switches and hydraulic motor, greatly simplifying maintenance. When Pak-Mor introduced a similar product the following year, EMCO filed a patent infringement lawsuit. However, a jury found that the competition's Link Retriever had not infringed the Ebeling patent, a decision that was upheld on appeal.

The economic conditions of the late 1970s had spurred some cities to automate their refuse fleets, due to the proven savings and efficiency. These same factors also led to the demise of EMCO, as the malaise carried over into the early 1980s. Their products were still in demand, but the small company had to borrow at crippling interest rates, in excess of 20-percent, as did their potential customers. About 300 cities had gone to some kind of automation in the previous decade, but the trend was downward, as many were now 'waiting out' the recession. Franklin Ebeling sold his company to an investment group, but under this new ownership, EMCO was soon in receivership. Although there may have been other interim owners, EMCO Manufacturing Corporation was eventually purchased by Panther Summit Industries of Raleigh, North Carolina in 1986. At that time, an entirely new modern ASL design appeared under the EMCO badge, looking much like an enlarged version of the Athey CWC300, fitted with an automated grabber-type lift for wheeled containers. The new owners then acquired Truxmore Industries the same year, and would ultimately combine everything into the Rand Automated Compaction Systems family by 1987.

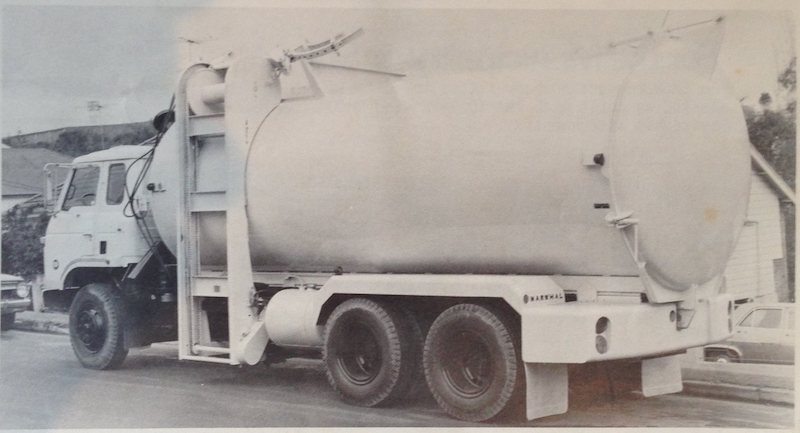

Late 70s EMCO with the original chain-rail type hoist, 3-cubic yard steel container

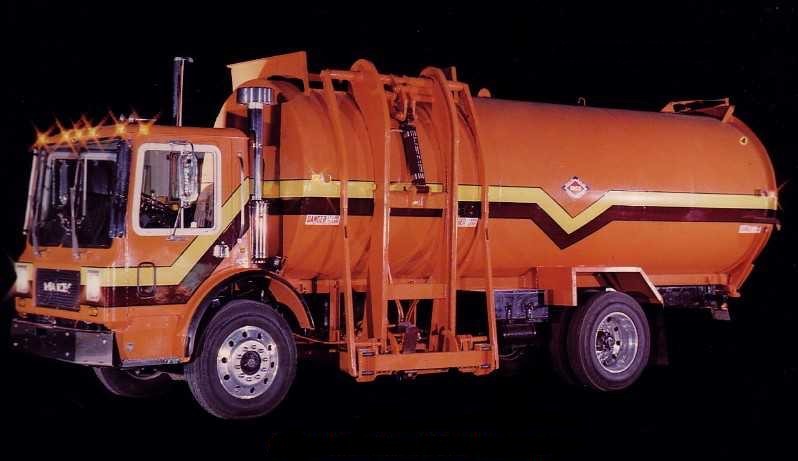

Identity crisis: Australian hybrid consisting of an EMCO body and chain hoist, Government Innovators gripper arms, sold under the "Rapid Rail" name!

The Pawnee Plastics wheeled 82-gallon Poly-Cart offered by EMCO in the late 70s

1980 ad announcing the new EMCO lift mechanism

Alley container route in St. Louis, handling 1.5 yard polyethylene containers

Big RB30 EMCO with gripper arm for Glendale, Arizona

RB-30 on a Mack MR, shows off the new linkage lift introduced in 1980

Long 2-stage cylinder projects well past blade. 1st stage only was used for packing, 1st and 2nd combined for ejection

The linkage-type arm in operation, with a total left and return cycle time of 10-16 seconds

EMCO survivor found in the Pacific Northwest (see link below for more images)

The last EMCO design was this ASL for 90/300-gallon wheeled carts, introduced around 1985-1986.

Descended from the Cobey/Athey Tite-Pak MSL, it has subsequently been sold under numerous badges

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US3841508A |

Refuse vehicle with a semi-automated ... |

Ebeling, et.al. |

EMCO |

September 27, 1972 |

|

US3910434A |

Mechanically actuated side loading... |

Ebeling, et.al. |

EMCO |

October 29, 1973 |

|

US3944092A |

Container emptying device |

Ebeling, et.al. |

EMCO |

February 3, 1975 |

|

US4090626A |

Trash handling device |

Ebeling, et.al. |

|

October 18, 1976 |

|

US4427333A |

Apparatus for handling refuse containers... |

Ebeling |

|

August 25, 1981 |

|

US4669940A |

Loader for a vehicle body |

Englehardt, et. al. |

EMCO |

May 22, 1984 |

|

US6494665B1 |

Container dumping apparatus... |

Bingman |

Central Tank |

July 13, 2000 |

REFERENCES

The Plainview Herald: Ebeling Manufacturing Brought Mechanization to Trash Collection

By Dough McDonough, November 13, 2009

Rand Automated Systems

By Eric Voytko, Classic Refuse Trucks, April 5, 2009

Classic Refuse Trucks in the Pacific Northwest

By Bill Tetrault and Zachary Geroux, Classic Refuse Trucks, 2009 (Pictures of EMCO found in Oregon)

Open Jurist: Ebeling vs. Pak-Mor Manufacturing Company (1981 appeals court ruling)

World Wastes, July 1986: News item on the assets of EMCO Mfg. being purchased

Donald F. Norris Cart-Based Automated and Semi-Automated Residential Refuse Collection

(1983) Publications Archives, 1963-2000. Paper 181.

Mechanical Collection Puts Lid on Refuse Infaltion

By Maynard Dils, American City Magazine, January 1977

St. Louis Automates

Solid Wastes Management, May 1982

Vintage EMCO Literature in PDF at the Classic Refuse Trucks Library

|

12/08/24

© 2024

All Rights Reserved

Logos shown are the trademarks of respective manufacturers

Photos from factory brochures/trade advertisements except as noted

|

|

| |