Glover, Webb & Liversidge

(Continued)

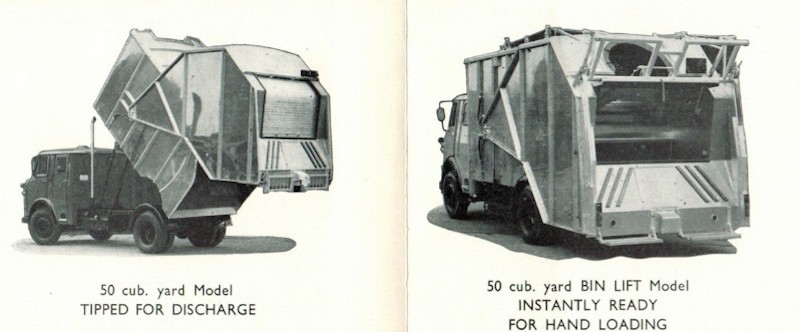

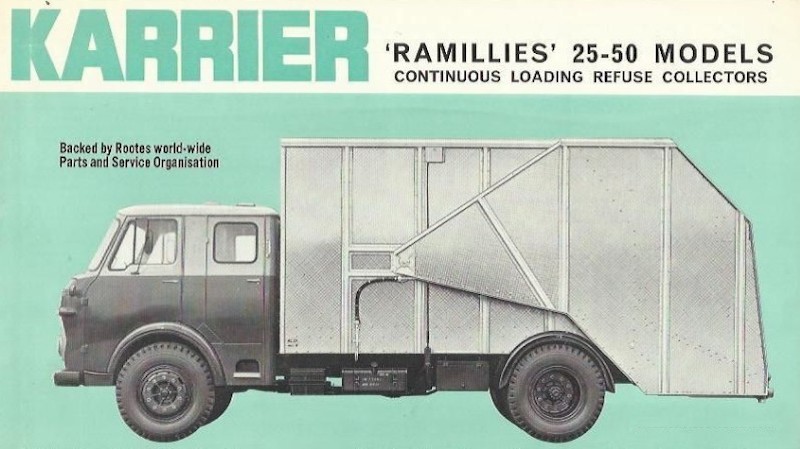

THE RAMILLIES

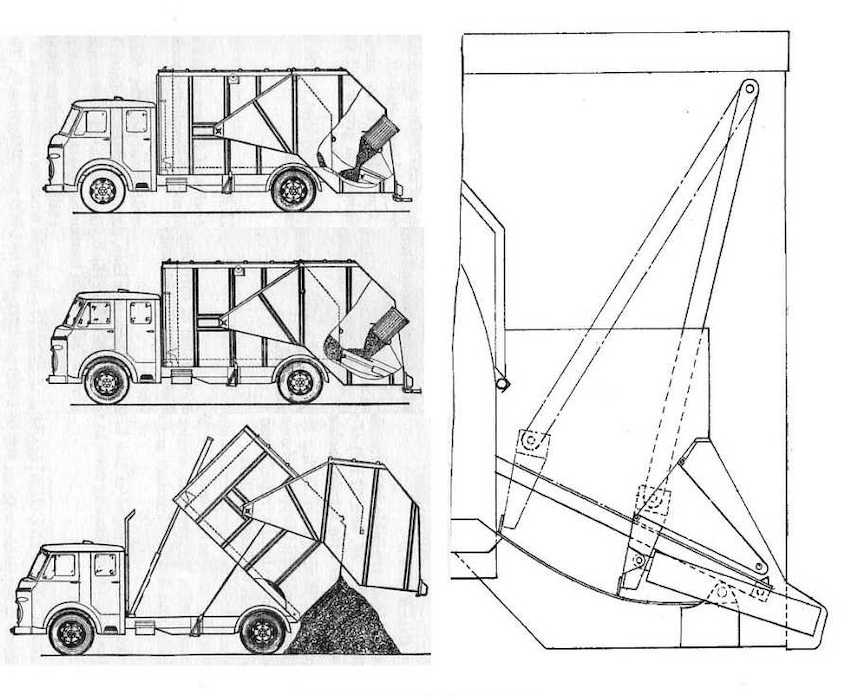

In 1962, Glovers had added a modern continuous-loading compression refuse body in the form of the Ramillies, which looked almost like a clone of the SD Pakamatic, but in fact had more in common the Blenheim. The packing plate was guided by long vertical links, and imparted a crushing force on the refuse against the radiused hopper floor, as well as the refuse already in the body. Unlike the Blenheim, a single hydraulic packing ram was utilized, located directly behind the packer plate. Cycling was continuous, with a follower plate to keep refuse from falling back behind the blade. Intermittent operation of the mechanism was also possible.

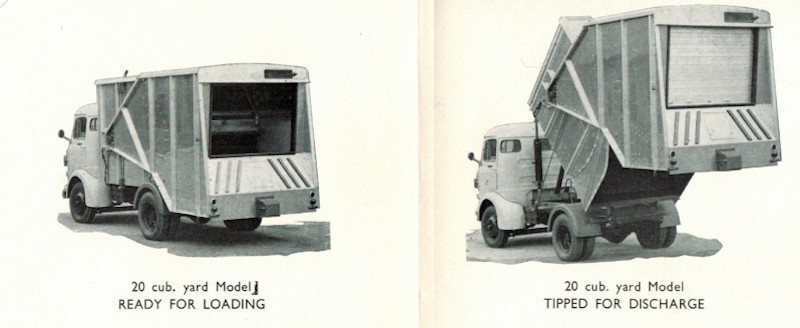

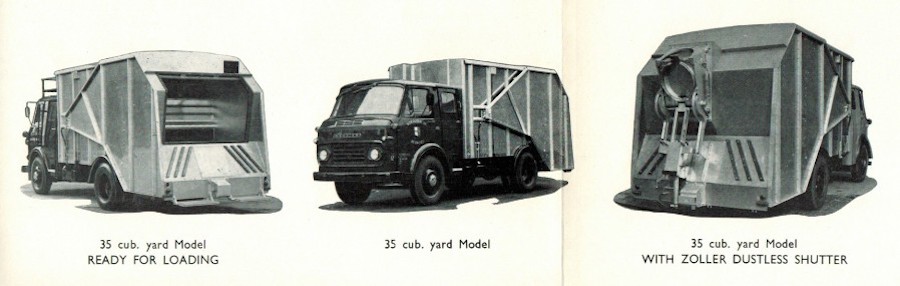

Ramillies rear loaders were available in 20, 35 or 50-cubic yard capacities. To comply with new weight regulations on motor trucks, aluminum alloys were used extensively in the body, a practice which would see widespread use in Britain. Unloading was by conventional means, with a tailgate hinged to the body side walls, which automatically raised upwardly as the body was tipped. As during the 1950s, Glovers favoured Karrier chassis, and had a good working relationship with that company.

So closely were the two companies associated, GWL bodies were often advertised as 'Karrier' models by the chassis builder

THE RAMILLIES BINMASTER

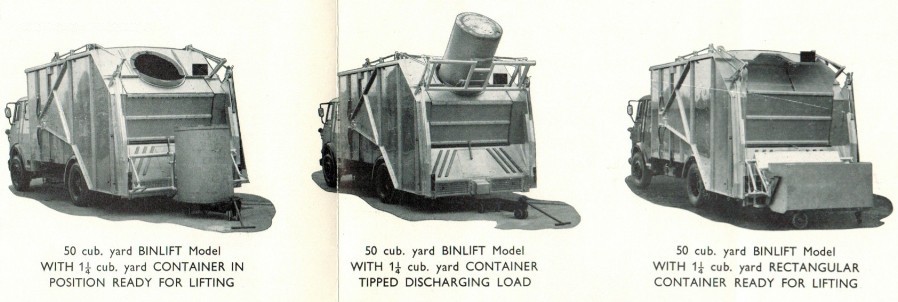

In addition to the various binlift attachments which could be fitted to the standard Ramillies body, a sub-series dedicated for commercial container loading evolved which was dubbed Binmaster. Although officially part of the Ramillies family, and appearing almost identical when viewed in profile, the packing mechanism was completely different. Harking back to the Sovel-influenced mechanism of the Loadmaster, Binmaster employed a pendulum packer blade and retractible-prong load retaining gate. Packer cylinders were relocated behind the blade, and close to the hopper sidewalls, which freed up the roof of the tailgate for the high-mounted loading aperture. This combination made for a generous hopper capacity, and a continuous-cycling hydraulic system kept it clear. It shared its tilt-to-dump alloy body with the standard Ramillies, as well as an all-steel ejection-discharge body introduced around 1970.

Early Binmaster emptying a Paladin bin

Later Binmasters employed ejection unloading

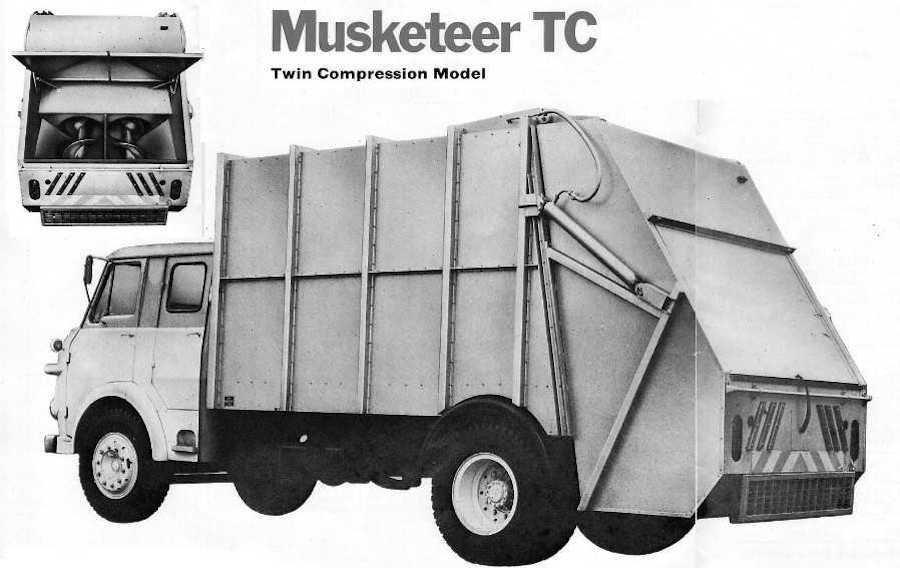

MUSKETEER REAR LOADER

Making its debut at the Public Works and Municipal Services Exhibition in November of 1964 was the all-new Musketeer, which employed a hopper-mounted double Archimedes screw to compress the refuse. Variants of the Musketeer would include a single-screw design, which resulted in weight savings and mechanical simplification. A voracious eater, the continuous loading Musketeer became popular seller in the expanded GWL lineup of the 1960s.

With a simple loading mechanism and aluminum alloy bodies, Musketeers were economical machines, able to legally carry more refuse. The tailgate was raised by cables, which were tensioned by the body as it rises to tip the load. This eliminated yet more dead weight from the body. As with the Ramillies, light-alloy tipper bodies were eventually joined by full-ejection versions. Despite the spate fresh new designs of the 1960s, the next decade would see the company moving to yet another all-new concept for their rear loaders.

Musketeer tippers had alloy bodies with cables to automatically raise the tailgate

Later ejection bodies had all-steel construction and hydraulic lifts. Ejector plate moves incrementally forward in the body during the continuous loading operation.

Bin-lifting equipment was easily adaptable to the Musketeer

With twin screws and ejection unloading, the Musketeer TC delivered high compaction with high-speed loading. Screws were driven by a

rear-mounted

double reduction gearbox, with over-running clutch to protect unit from damage. In the event of a jam up, it could be

manually cranked in reverse.

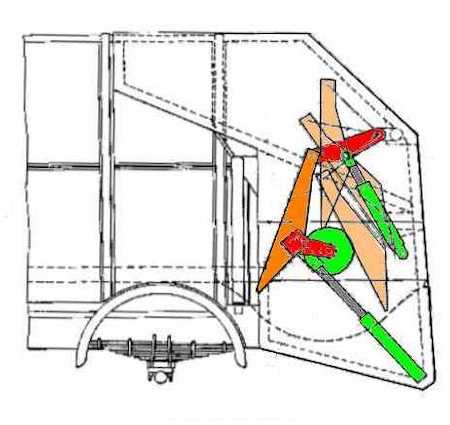

GRENADIER

1974 brought the first all-new Glover, Webb & Liversidge rear loader in a decade, the Grenadier. This was a "revolving blade" type loader, with a mechanism based on the Fernand Rey design and already in use by SEMAT and Shelvoke & Drewry. Glover's Grenadier differed in that it was an intermittent type loader, and used two large hydraulic rams to to drive the main rotors, with the addition of two smaller rams which acted upon the stabilzer arms. It was complex, and thus not as attractive as the simple Musketeer screw loader, which still remained in the product line. In 1975 the Company moved to Hamble, near Southampton, where refuse collection vehicle production continued with bodies simply badged as "Glover".

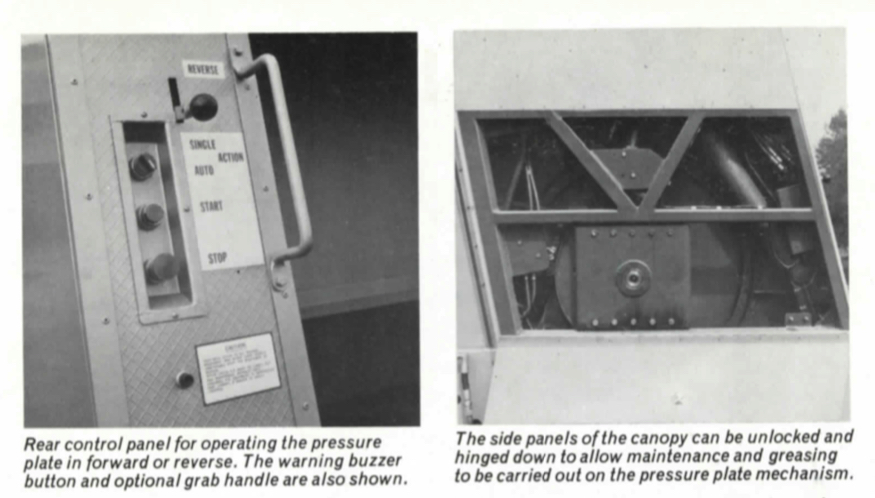

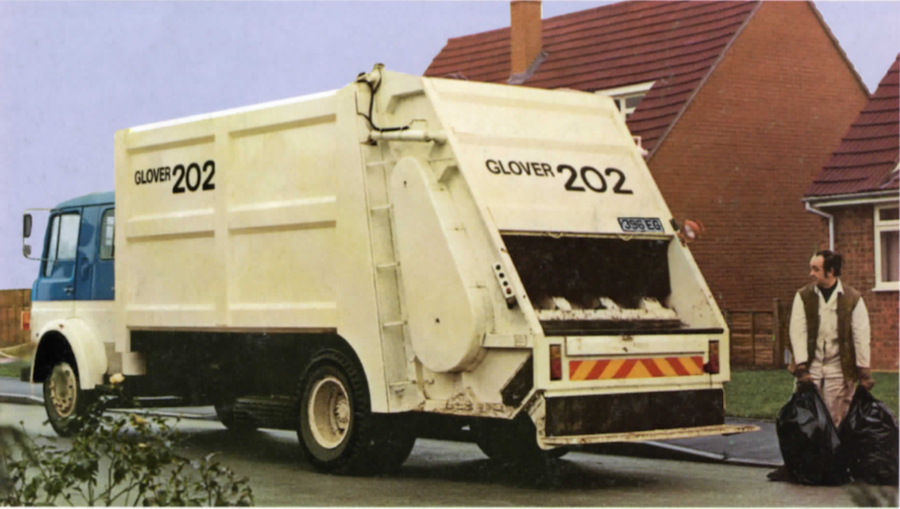

THE GLOVER 202

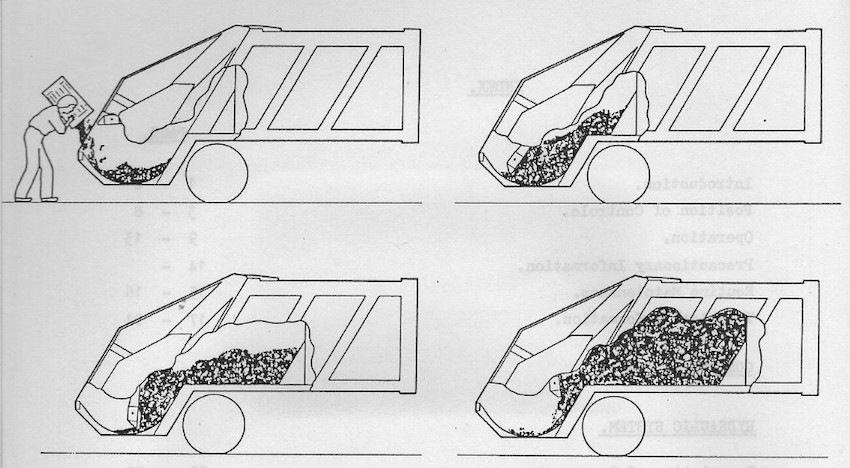

The Grenadier was replaced in 1977 by the 202, which was a compression loader similar to Shelvoke & Drewry's first-generation Revopak. The cumbersome mechanism of its predecessor was replaced with a twin chain-driven, continuously-rotating plate powered by a 40 HP hydraulic motor, a cross-shaft and reduction gearing. The hydraulic pump was driven directly from the vehicle crankshaft, for continuous operation and reduced noise levels. A variety of chassis could be specified, including SD, Dennis, Leyland or Dodge.

An early-model 202 with lift attachment empties a Palladin bin

202 body on a Mercedes-Benz truck chassis for the German market

202 on the job

THE LOADMASTER

The final version of the GWL revolving packer resurrected the old Loadmaster name, originally used on Glover's pendulum packer of the 1950s. The New Loadmaster was a continuation of the 202 design, with an updated slant-pillar body. From 1983, the company traded under the shortened moniker of Glover Webb Ltd., and changed hands from The Charringtons Group to The Coalite group in 1986. During this period, the company also made military/security vehicles, and was sold yet again in 1991. After almost 275 years in business, Glover Webb was again sold in 1994 to GKN Defense, which ultimately dissolved the company by 1998. Few, if any, refuse bodies were likely to have been produced since the late 1980s.

Unlike rival Revopak, Loadmaster's packer plate was chain driven, and uutilized a closed plate instead of the tine rake favored by S & D.

(Left) Picture taken in 1988 of two new Leyland Municipal Freighters mounted with Glover Webb Loadmaster bodies. Registered as E784 FWP and E788 FWP respectively. These vehicles were fitted with a Granning lift axle enabling their gross weight limits to be raised to 19,000KG. Livery is that of Worcester City Council and the picture was taken in their depot.

(Right) Photo of the exhibition stand of Glover Webb Limited (Formerley known as Glover Webb & Liversidge) in 1988. The green Loadmaster truck shown is one of the two vehicles in my previous photo taken at Worcester City Council - Yes, they did initially paint them to the wrong colour! -Phil Clifford

|

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

GB980086A |

Improvements in....Refuse Vehicles |

Evans, et.al |

Glover, Webb & Liversidge |

December 26, 1961 |

|

GB1109317A |

Improvements in....Refuse Vehicles |

Evans, et.al |

Glover, Webb & Liversidge |

November 4, 1963 |

|

GB1114420A |

Improvements in....Refuse Vehicles |

Greenland, et.al |

Glover, Webb & Liversidge |

August 27, 1964 |

|

GB1212680A |

Improvements in....Refuse Vehicles |

Greenland, et.al |

Glover, Webb & Liversidge |

December 19, 1966 |

|

GB1498955A |

Refuse Collecting Vehicles |

|

Glover, Webb & Liversidge |

April 2, 1975 |

|

GB1588133A |

Refuse Collection |

|

Glover, Webb & Liversidge |

December 6, 1977 |

REFERENCES

"British RCV Memories" By Trevor Wood

Classic Refuse Trucks

Vintage Glover Literature in PDF at the Classic Refuse Trucks Library

New Appliances at Scarborough (Grenadier)

The Commercial Motor, 14 June 1974, page 38

Waste Collector Opts for Simple Life (Glover 202)

The Commercial Motor, 1 April 1977 page 24

Neville Charrold Goes To York

The Commercial Motor, 19 July 1986 page 7

York Gets Wet with OMT (Sale of Glover Webb subsidiary)

The Commercial Motor, 28 February 1991, page 16

|

1/17/10 (revised 2/15/15, Updated 3/26/17)

© 2010, 2015

All Rights Reserved

Logos shown are the trademarks of respective manufacturers

Photos from factory brochures/trade advertisements except as noted

|

|

| |