Heil Conveyors

Including the Baldt Loader and Conveyo-Pak

THE HEIL CONVEYOR

Since 1937, the New York City Department of Sanitation (DSNY) had been using an escalator/conveyor-loader collection body of their own design. Heil is believed to have built one the first testing prototypes used by the DSNY that summer, and along with Gar Wood Industries, had won bids to build large numbers of these bodies in the years that followed. Rather than marketing the DSNY body nationally under license, Gar Wood instead developed their famous Load-Packer body which would dominate the industry in the 1940s. The Heil Company evidently saw promise in the DSNY concept, but instead opted to build their own variation to be sold under the Heil name beginning in 1938.

Heil had been building enclosed, non-compacting bodies for years, and had maintained an on-and-off relationship with Colecto since the late 1920s. But the Heil Conveyor would be a milestone in their history, being the first mechanized refuse body designed, built and advertised by the company as a Heil product. It marks the point where the company began to seriously compete in the refuse body industry, and would increase the Heil presence in a few major municipal fleets. The Heil Conveyor and the Colecto (which was by then a more-or-less captive brand) formed the nucleus of the company as we know it today, as one of the world's largest producers of refuse collection equipment.

1939 advertisement for the Heil Conveyor

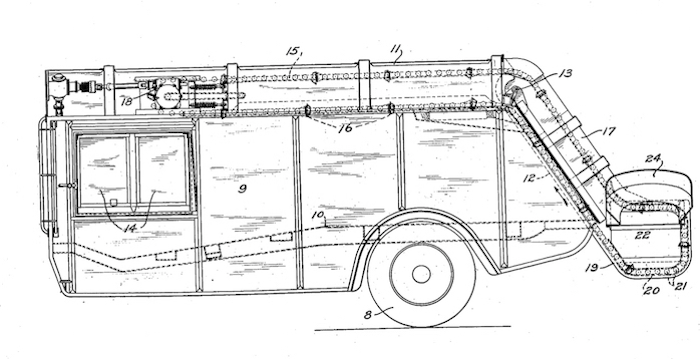

Heil Conveyor cut-away drawing illustrates wide chain loop at loading boot, which forms opening to hopper at either side

The Heil Conveyor was clearly inspired by the DSNY escalator-loader, and shared many of the same features. It used an endless-chain conveyor which lifted refuse from a rear loading boot, carried it up to the top of the body and trimmed the load as the refuse accumulated within. Side loading doors accommodated bulky items, as well as hand-loading during early stages of the load. There was no real compaction, but an even load distribution was achieved, especially with the denser refuse of the 1930s. It was particularly well-suited for granular material, such as ash and even dirt, although its many moving parts were vulnerable to abrasive wear. A 16-yard body was initially offered, and a 21-yard version followed soon after.

The escalator-conveyor has been around a long time, and had been used to load and move material in mining, construction, agriculture and manufacturing. Its application in refuse handling (and the first known refuse truck patent ever filed in the United States) was for a conveyor loader designed by John Kelly in 1909. However, the first conveyor refuse truck known to have actually been built was in 1931 by Automatic Truck Loader Company of New York. This early loader may have been what spurred the DSNY's interest in the concept, which they adopted in 1937. Far from merely copying these pioneers, Heil made a significant improvement to the loading boot on their unit, and clearly came away with a better design. Early escalator-loaders all had a single loading aperture at the rear of the tailgate, through which refuse was dumped on top of a continuously moving conveyor chain. As refuse was loaded, it had to pass through the moving conveyor flights as they descended into the hopper, and then was lifted into the body as the flights rounded the lower roller and ascended back up the tailgate. This presented dangers to the crew and the cans, which had to be kept out of direct contact with the moving flights. Only one man could load at a time, having to support his refuse barrel (or sack) in the upright position until the conveyor had digested its contents.

The Heil version ingeniously eliminated the dangers of contact with moving parts by placing twin loading apertures on the sides of the conveyor boot, allowing two men to load simultaneously from either side of the street. Special guide tracks carried the conveyor drive chains in a wide arc, through which refuse was loaded without obstruction. The moving flights never passed by this opening, protecting men and equipment from harm. Once it was safely inside the hopper, the refuse was carried up and into the body in the conventional manner. Large loading flange extensions could hold a small amount of refuse until the conveyor had time to digest the load, letting the crew dump their cans without waiting in most cases. Either opening could be closed off by a steel door for safety if it was not being used.

The Heil Conveyor was built for the national market, even as Heil was also building DSNY-designed escalators to fulfill contracts they had been awarded by the City of New York. Thus, the company enjoyed the best of both worlds, building large numbers of bodies for the DSNY, while selling their own patented Conveyor to other cities. Providence, Milwaukee and Chicago were their biggest customers, the latter making purchases both before and after the Second World War. Milwaukee built their own special version, mounting 21-yard Heil Conveyors on Fruehauf semi-trailers towed by FWD tractors. The system freed up the truck tractors for other uses when not collecting refuse.

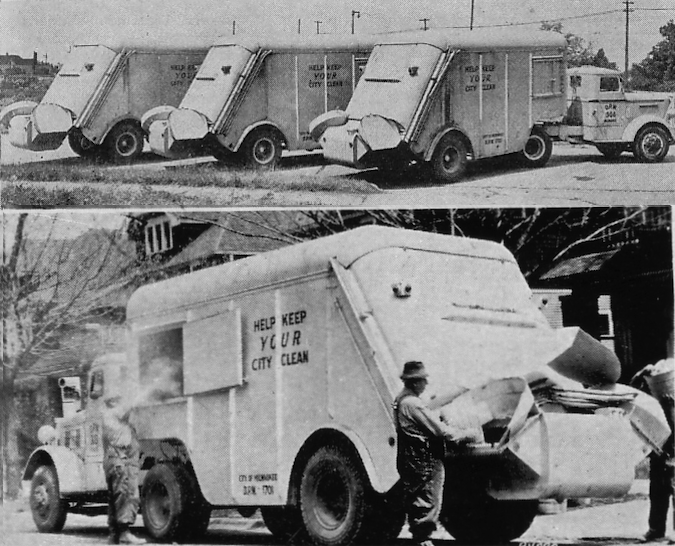

Milwaukee had a small fleet of 21-yard Heil Conveyors by 1942, mounted on Fruehauf trailers and pulled by FWD truck tractors

SIDE LOADING VERSUS REAR LOADING CONVEYOR:

Dual rear loading openings on Heil Conveyor (left) sped the loading process, and kept moving flights away from crew and trash barrels.

Compare with DSNY conveyor (right) with rear aperture: flights constantly pass by the opening, posing more of a hazard to men and equipment

|

HEIL CONVEYOR: WIDE HOPPER VERSION

A group of Heil "wide hopper" Conveyors still in Chicago's fleet in the mid-1960s, although probably out of service at that time

Post-war production of the Heil Conveyor resumed with a re-designed version featuring a wider hopper and conveyor, which was now almost the full width the body. The side loading openings were also enlarged, with wide diameter chain loops in to which refuse could be loaded faster. The City of Chicago purchased a large fleet of the improved models, augmenting their existing fleet and was undoubtedly the biggest user of the Heil Conveyor. Many were still owned by the city by the 1960s, although they were probably in reserve status by that time.

Heil discontinued their Conveyor during the early 1950s, about the time the company began contemplating an all-new compaction rear loader. During most of its production run, it was sold alongside the Heil Colecto and Colecto-Pak bucket loaders, which proliferated during the post-war period. Some cities, such as Milwaukee, used both models. However, it was the batch-loading packer truck, as pioneered by Gar Wood, that softened demand for conveyor-type loaders, especially as household refuse was become lighter and required compaction. When the Leach Packmaster arrived in 1947, it was probably apparent to all that the hydraulic packer body would soon dominate the industry, in one form or another.

City of Chicago Heil Conveyor wide-hopper version on GMC T-Series cabover

York, Pennsylvania owned this 1952 Heil Conveyor on Autocar chassis

BALDT LOADER AND HEIL CONVEYO-PAK

Thomas T. Baldt was employed in the motor maintenance bureau of the New York City Department of Sanitation (DSNY). In 1946, he designed and patented an improvement to the escalator-conveyor loaders already in widespread use with the department. Baldt's invention consisted of a packer mechanism which assisted the loading conveyor to achieved greater density. The packer was a two-bladed rotary vane with scraper plate, which received refuse from the conveyor flights and forced it into the body at floor level. The rotary vane was driven by the same motor as the conveyor. The hinged scraper plate removed refuse from the faces of the rotary blade, served as an internal load retainer and then assisted in packing as the body became filled.

The only known photo of DSNY Baldt loader, and experimental unit bearing the Heil nameplate

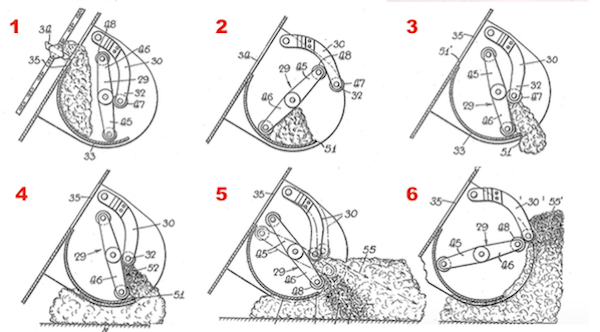

Packing sequence of Balt loader: (1) Conveyor carries charge of refuse from hopper, deposits it in packing chamber, (2) dual-vane rotary blade

sweeps refuse forward into chamber while lifting scraper blade, (3) refuse forced into body as scraper blade wipes face of rotary blade,

(4) during initial load phase, refuse falls on to floor of body, (5) as body fills, refuse is moved radially outward from chamber,

(6) with body nearly filled, compaction occurs from rotary blade and lifting of scraper blade up against load

At least one prototype of the Baldt loader was constructed and tested by the DSNY in the late 1940s. The photo of this unit shown here clearly indicates that it was built by The Heil Company, using an old non-compacting enclosed dump body on a GMC chassis, with a specially modified tailgate assembly. This Baldt loader remained in service through at least 1951. Additionally, the department had 42 other Autocar trucks with "Heil escalator-compactor bodies" in the muster rolls that year. These may have been converted 24-yard bodies, or possibly the rare Heil Conveyo-Pak.

Little is known of Conveyo-Pak, which was is in at least limited production by 1949. Since Heil had built the Baldt prototype, it is highly probable that they licensed the design for their own use. Under a City policy established in the 1930s, the DSNY had the right to use Baldt's design free of royalties, but the inventor was free to sell his patent to any other interested parties for profit.

The Heil Conveyo-Pak shown here is believed to have been owned by the City of Yonkers. It clearly uses a standard Heil Conveyor body with the pre-war style narrow-width loading boot. The bulging tailgate door appears exactly as the one on the Baldt prototype made for the DSNY.

The DSNY experiments with the Baldt loader, and a brief fling with the Gar Wood Load-Packer ultimately came to nothing. When City Tank Corporation changed their Roto-Pac to an escalator-compactor design in 1951, the Department adopted it as their residential truck and purchased hundreds of them through the 1960s. This doomed the Conveyo-Pak, but in retrospect was probably good for Heil. Apart from the DSNY's love affair with the conveyor-type loader, this method was rapidly becoming obsolete, and the future of the refuse body industry was headed in an entirely different direction. Gar Wood had obviously realized this a decade earlier, and never bothered with conveyors outside of their DSNY contracts. Moving away from this antiquated technology led Heil to pursue different designs, which would ultimately carry them to new heights of success within the industry, and even back to the Big Apple some day.

PATENTS:

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US945330 |

Vehicle (early conveyor loader) |

John Kelly |

|

January 27, 1909 |

|

US2167148 |

Refuse Collecting Vehicle (Heil Conveyor) |

Frentzel, et al |

Heil Co. |

June 13, 1938 |

|

US2496192 |

Automatic Vehicle Loader (DSNY Baldt Loader) |

Thomas T. Baldt |

|

December 13, 1946 |

REFERENCES

Classic Refuse Trucks: Automatic Truck Loader Co. January 10, 2016

American City Magazine: New York City Cleaned by $20,000,000 Collectors and Sweepers April 1951, page 13

|

7/2/16

© 2016

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

| |