Load-Lugger

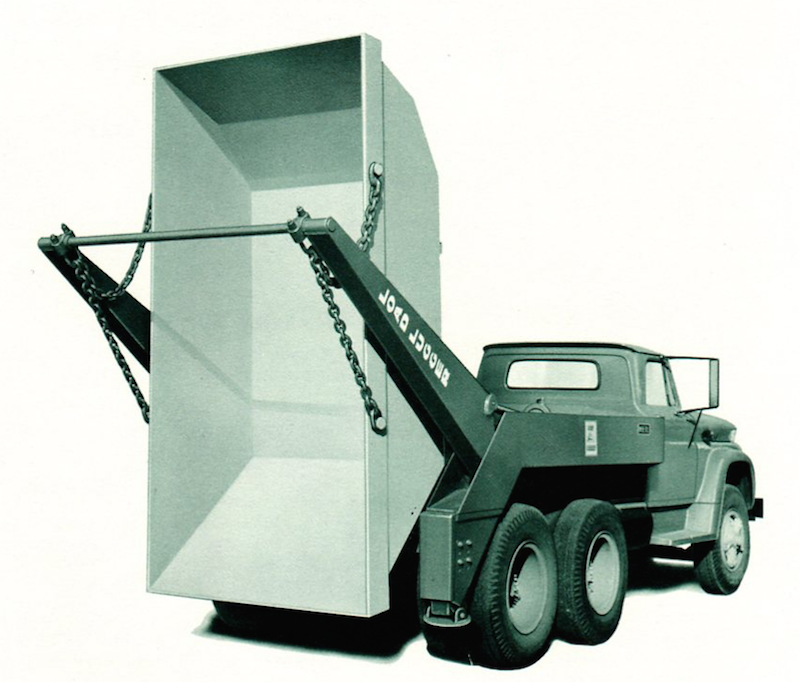

Heil Load-Lugger Series 3878 (9,000 to 12,000 lbs. lifting capacity) on International Harvester Loadstar

Following the smashing success of the Colectomatic Mark II the previous year, Heil further expanded their refuse body line with the acquisition of Load-Lugger in 1961. Load-Lugger had been established back in the 1930s, in the same city as Dempster (Knoxville, TN) and had been the longtime competitor of the Dempster Dumpster detachable container system. The Load-Lugger used a pivoting boom which reached backward and lifted containers from ground level to the truck bed. The system was popular in variety of industrial hauling applications, especially for scrap metal, but was also being used for refuse collection. Borg-Warner Corporation bought the company in the mid-1950s, and moved operations to Kalamazoo, Michigan. A roll-off was added in 1959, called the Huge-Haul, and tooling for both models was transferred from Michigan to the Heil Body and Hoist Division factory at Milwaukee. With the addition of Load-Lugger products, Heil had fired a shot across the bow of Dempster, reaching out for a piece of the growing detachable container market. Ultimately, Load-Lugger would be sold off decades later, but was great addition for Heil during the 1960s as the company transitioned from merely building rear loaders, to the manufacturing of a complete lineup of refuse hauling products.

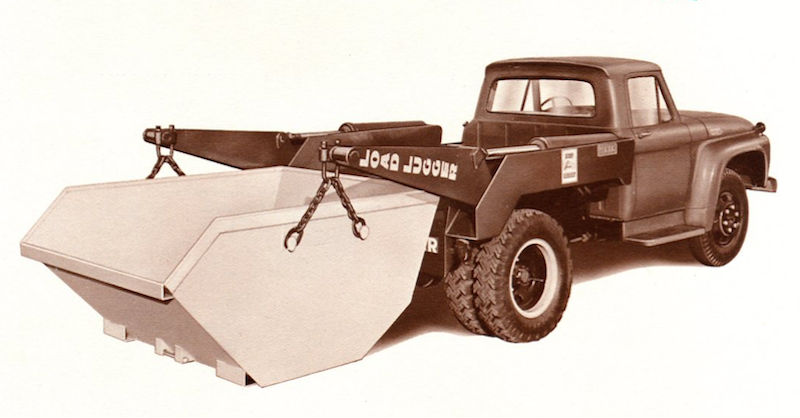

Series 1951 (6,000 lb. lift capacity) on Ford F-series

Series 2157 (9,000 to 12,000 lb. lift capacity) on Ford F-series

Series 3163 (10,500 to 15,000 lb. lift capacity), GMC

Series 5810 (15,000 lb. lift capacity) on International CO tilt-cab

Series 4696 (20,000 to 26,000 lb. lift capacity), GMC

Series 7420 (26,000 lb. lift capacity), Ford N-Series LCF

LOAD-LUGGER SATELLITE SYSTEM

The Satellite System consisted of a "master" container which was first loaded on to the truck bed, and then disconnected from the lift arms. The arms were then used to lift and empty 1 and 2-yard "satellite" containers much like the old rear bucket-loading Colecto-Pak. The satellite containers could be spotted at businesses, parks, etc., and the master container could hold the contents of about ten of the smaller cans. The system was available on Load-Lugger Series 4696 (12-yard master container) and Series 5810 (16-yard master). Regular commercial containers could also be hauled in the usual fashion by the Load-Lugger lift.

Series 5810 lifting a 1-yard satellite container to dump in its 16-yard master container

Series 5810 lifting a 2-yard satellite container

|

Heil Load-Lugger hauling grit removed from a municipal sewage treatment plant

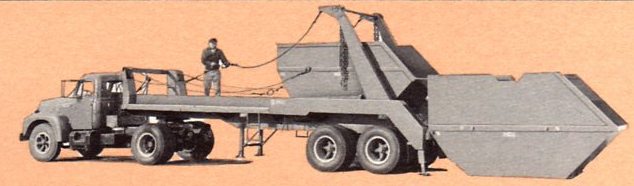

LOAD-LUGGER 2-CONTAINER SEMI-TRAILER

|

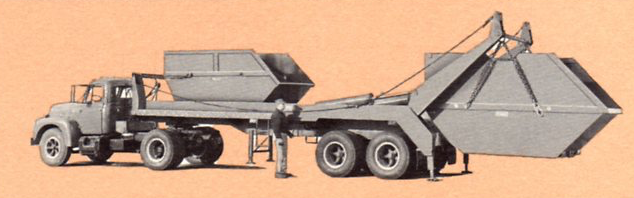

First container is loaded onto trailer and detached from lift arms. Drag cables on lift arms loop around pulleys at front of trailer, and are then attached to this same container

|

As lift arms extend rearward over second container, drag cables pull first container towards front of trailer

|

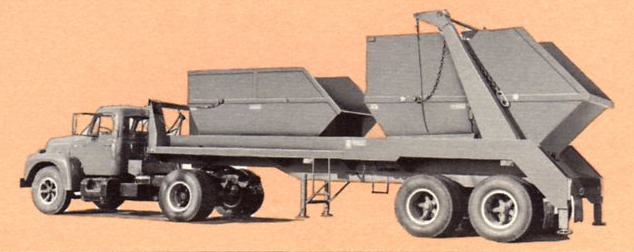

With lift arms fully extended over second container, first container has now been dragged to front end of trailer

|

Second container can now be hoisted on to rear of trailer

|

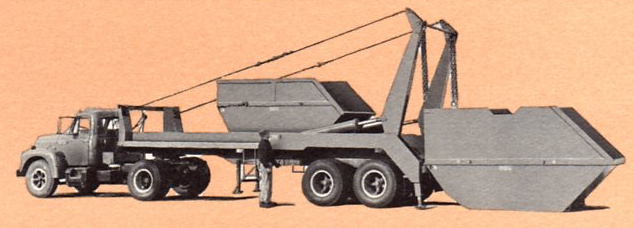

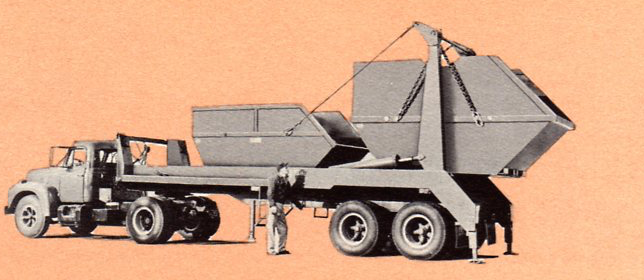

Both containers are now loaded on trailer, ready for transport or dumping (rear container)

|

Unloading is merely a reverse of the loading procedure, except that a shorter drag cable is directly connected from the lift arms to the first container

|

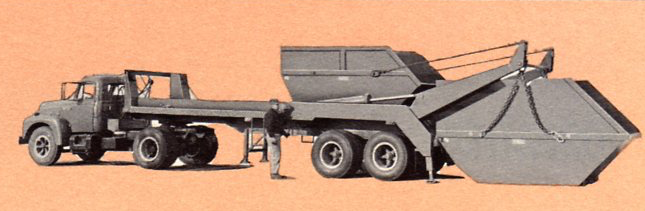

As rear container is lowered to ground, lift arms drag front container to end of trailer

|

5/29/17

© 2017

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

| |