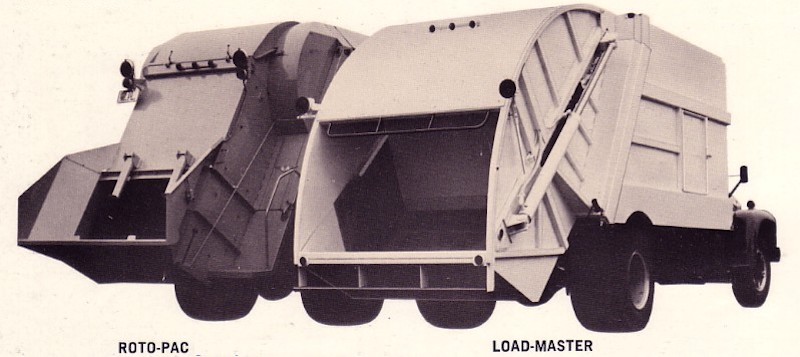

Above: 1964 Loadmaster LM-120 (20 cubic yard) refuse packer The biggest industry bombshell was the phenomenal Leach 2-R Packmaster, which introduced the world to the two-panel 'slide-sweep' concept in 1959 and was breaking compaction barriers. Additionally, the 2-R possessed a then unheard of crushing ability, virtually eliminating the need for separate bulk pick-ups. Another major advance in rear load refuse truck technology was Heil Company's revolutionary Duo-Press compaction/ejection system for their Colectomatic Mark II introduced in 1960. It must have been eminently clear to City Tank that the primitive Roto-Pac, with its chain flights and limited hopper capacity would never carry the company through the decade ahead. Against this background, City Tank began testing of various components for an all-new refuse packer in 1961, and a prototype unit was operational by late 1962 and sent out on the road for real-world testing. In a later press release, company president John G. Hagan remarked on the impressive performance of the new unit: "...We made available a prototype unit to a large eastern city, and asked the sanitation department to give it the most severe usage possible. We literally asked them to tear this test unit apart. We put it on the toughest collection routes, and ran it practically on a continuous basis for several months. There were no large or small malfunctions of the unit. With only normal maintenance, the Load-Master exceeded the strict engineering performance that had been predicted. Our experience indicates that this unit out-performed, out-packed and out-worked any batch packer we have used"

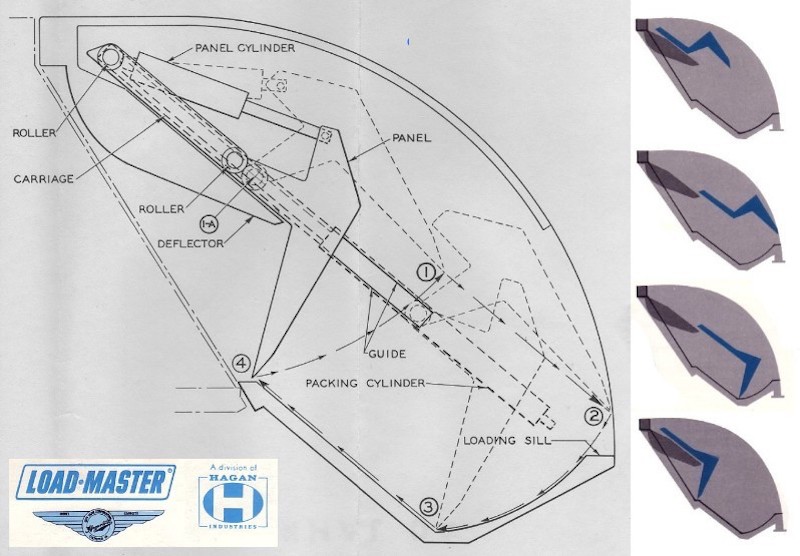

But it is the sweep panel that truly set the Load-Master apart from the 2-R. Whereas Leach used a flat sweep panel hinged to the slide panel, the Load-Master was L-shaped, with the hinged end effectively forming an extension of the slide panel. As a result, the sweep panel had a much shorter operating arc (90 degrees) between the fully closed and fully open positions, enabling the use of shorter sweep panel cylinders (16" stroke) and decreasing cycle time. In the drawing below, note also the lower edge of the sweep panel tends to arc upward and over the load as it opens (from positions 4 through 1) thus minimizing the pushing of loaded refuse backwards and on to the street. This effectively increased the useable hopper capacity, and positioned the sweep panel high over top of the load as the slide panel descended during the second phase of the packing cycle. The drawing below better illustrates the features of the Load-Master packer mechanism:

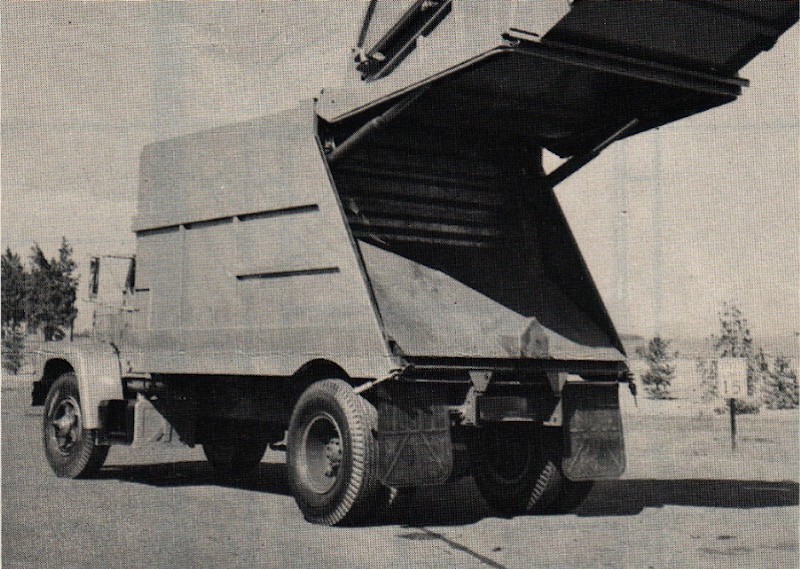

For unloading the LM-100, the tailgate was raised by single acting lift cylinders, concealed within the structure. It featured a full-travel, manually operated inclined ejector plate, powered by a telescopic ram mounted horizontally in the body. A protrusion in the bottom of the ejector plate housed the big end of the ram. Load-Master recommended leaving the ejector fully forward in the body (towards the vehicle cab) during normal loading procedures. Once the body became filled, a procedure was recommended whereby the panel was periodically extended and retracted to crush the load within the body, thus increasing the compaction density. This procedure (sometimes called "back-packing") was to be done only two or three times per truckload. In spite of Load-Masters recommendations, in actual practice many operators started their routes with the ejector farther back in the body. As the body filled, and the packer began to labor, the operator would then move the ejector forward incrementally to make more room, along with periodic back-packing cycles. This procedure somewhat mimicked the automatic action of the aforementioned Duo-Press system from Heil. Load-Master literature officially discouraged this practice, indicating it could result in decreased capacity due to 'voids' in the load being created along the sides of the body.

CONTAINER LIFT SYSTEMS

7/4/10 © 2010 All Rights Reserved Photos from factory brochures/advertisements except as noted Logos shown are the trademarks of respective manufacturers |