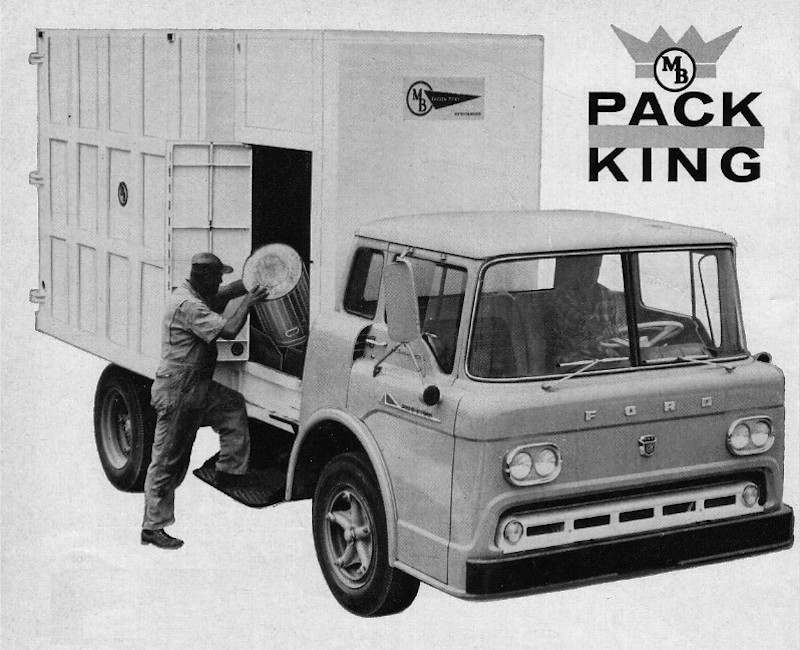

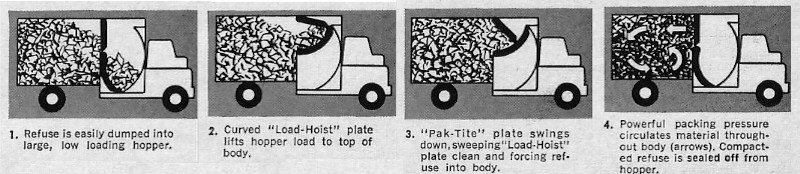

For 1961, M-B Corporation did a complete about-face with their refuse bodies. The cable operated, full-pack/full-eject side loaders were dropped, along with the Contain-O-Pack side load system, and were replaced with and entirely new design. The new model was the brainchild of James Weir, who had designed the original M-B Packer, but that is where the similarity ended. The new Pack-King was an all-hydraulic, partial-packing side loader with tilt-to-dump unloading...the complete opposite of the original M-B Packer produced between 1954 and 1960. Pack-King was one of the most interesting refuse trucks ever made. Not only was different than anything M-B had ever built, it represented a complete break with established side-loader engineering dating back to the Marion Refuse Compressor of 1934. Instead of a single, sliding packer plate, the Pack-King essentially took the hinged-hopper rear-loader packing system, first used on the 1954 Heil Colectomatic, and reversed it, so that the packer mechanism was located behind the cab and pushed rearward into the body.

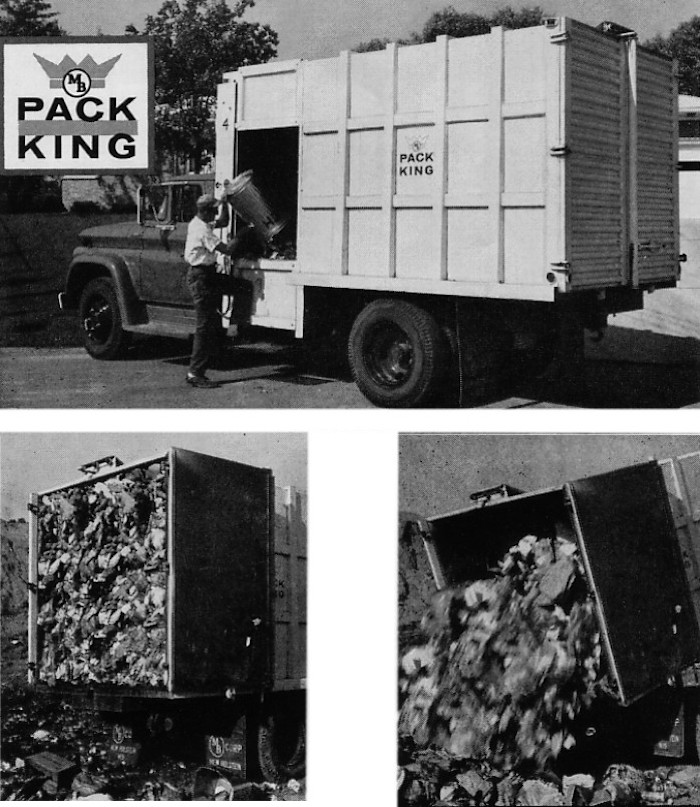

As with the previous models, the new Pack-King could be had in 14, 16, 20 or 24 cubic yard capacity. Twin outboard-mounted hoists raised the body for dumping, and a 4" taper helped assure clean unloading. No mention is made of container attachments; the Pack-King was strictly a hand-loaded unit.

As novel a design as it was, the Pack-King still retained the high loading height of its predecessor, a problem then being successfully addressed by some upstart West Coast manufacturers. Low-height, drop-frame side loaders such as the Shu-Pak were finding more and more adherents, and would become the favored side loader design with the advent of one-man and automated collection systems. After 1971, the Pack-King was no longer listed by M-B, leaving only a single 5-yard satellite packer, the Moto-Pack. In retrospect, the Pack-King was a heroic engineering effort by M-B to try and remain viable in the refuse body business. Adding hydraulic power to the old M-B Packer would have been an improvement, but would not have set it apart from the many competing side-loaders that were flooding the market in the early 1960's. The Pack-King appears to have been a well-engineered unit, and remains one of the few side loaders ever built with a positive load-retention system. In later years, the Pack-King method would once again be employed by Canadian manufacturers Wittke (Burro) and Haul-All (Curbster).

SELECTED PATENTS

|