Norba AB

Blomstermala and Kalmar, Sweden

Maskinfabriks AB Norrbacken started in 1917, and was so-named by their parent company Swedish Match AB which had purchased a forge in Blomstermala. The forge was much older, a carriage works that was founded in the 19th century. Their business was the manufacture of equipment for the collection of refuse, such as bins and wagons for what was then a horse-drawn industry. By the mid-1930s, motorized refuse trucks were being built, and compaction bodies were introduced at the end of the decade.

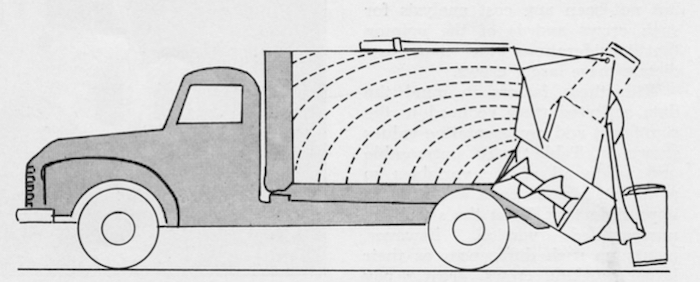

Credit for the Norba compaction body belongs to Hilding Linde (1883-1968), the company director who had studied in Germany and England. He held scores of patents for refuse trucks, bins and lifts, and clearly was the driving force that would make Norba an international success. His first patent for the screw-type loader was filed in Sweden in 1935, and was based on a design pioneered by Krupp in 1921, with a rotating spiral screw carrying refuse from a rear loading trough into an enclosed tipper body. Linde's design differed in that the screw was much shorter, terminating just past the trough, whereas the Krupp screw ran the entire length of the body. What would become the Norba System was actually superior to Krupp, developing the same compaction with lighter weight and simplified construction. While the Krupp design would fall from favor, the Norba System flourished, and would ultimately develop a worldwide popularity in the post-war years. Linde's basic design is still in use to this day on modern screw-type compactors.

Their products were built at factories in Blomstermala and Kalmar, and early models for the domestic market were typically fitted with dustless shutters, as was the practice in many European cities using standardized steel bins. The screw system worked well in this application, slowly churning and crushing each batch of refuse under the seal of a fully enclosed hopper. Round bodies were produced, but the lightweight sheetmetal box of roughly rectangular shape was more typical. The trade name "Norba" was most likely adopted as more bodies began selling internationally, with the first imported models were introduced in Great Britain in 1962. Initially sold through distributor Bech, Neale & Co., the Norba proved to be so popular that a factory branch was establish at Letchworth. The augers and some associated parts still came from Sweden, with everything else made in the UK.

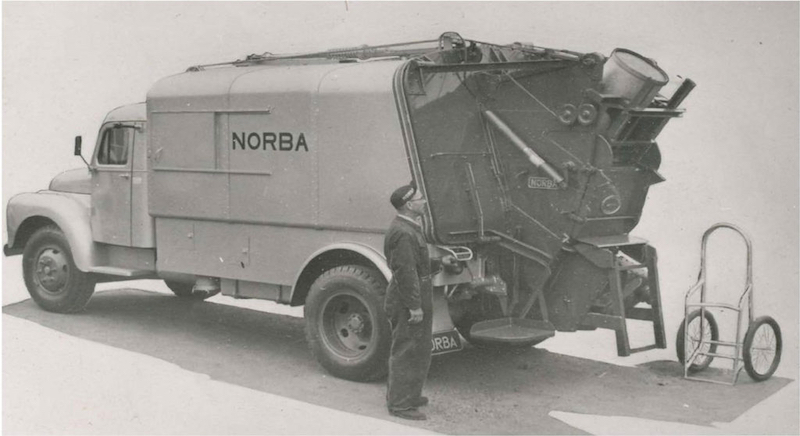

Typical Norba body of the late 1950s, constructed of lightweight, flexible sheetmetal

Norba trade ad from 1955

Cross-section shows screw-auger, dotted lines indicate theoretical zones of compression within the body

The robust screw rotates at 12-16 RPM and can handle domestic refuse, or splinter the bulkiest objects for superb compaction

Norba with dustless bin loader on rounds in Gothenburg, circa 1960

Empty bin is carted away as screw digests the refuse

Norba Mini, an 8-cubic meter body for congested areas, mounted on a Mercedes-Benz LP808

The Mini could be fitted with hoist suitable for containers up to 800 liters

Tailgate pivoted on side-mounted bearings, instead of the usual top hinge

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US2223690A |

Refuse collecting container |

Linde |

|

November 4, 1936 |

|

U.S. Patent List |

(Search European Patent Office for original patents |

Linde |

|

various |

REFERENCES

Norba AB Swedish Wikipedia

Krupp at Classic Refuse Trucks, by Eric Voytko, October 2, 2016

|

10/13/19

© 2019

All Rights Reserved

Logos shown are the trademarks of respective manufacturers

Photos from factory brochures/trade advertisements except as noted

|

|

| |