Shelvoke & Drewry

'T' TYPE PAKAMATIC

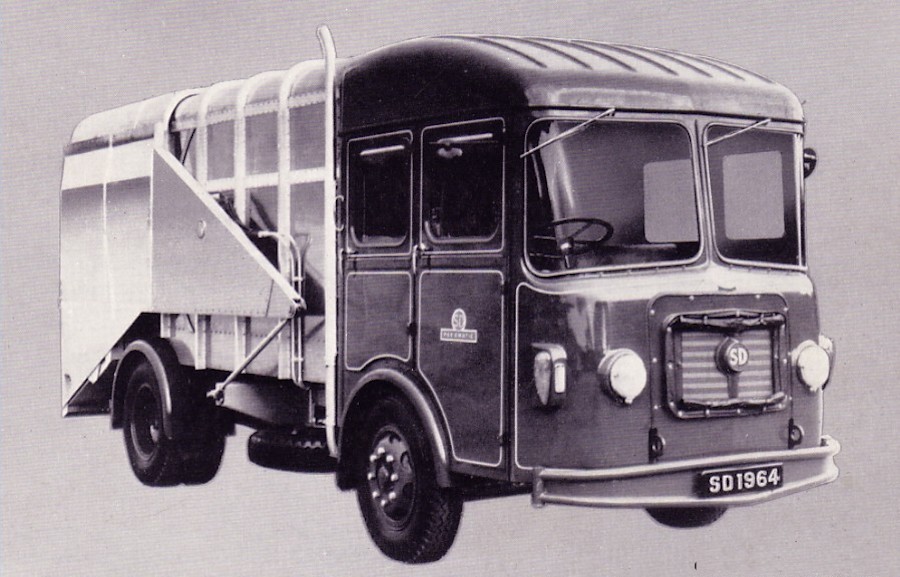

1964 Pakamatic on S & D 'T' Type chassis

By 1960, a more efficient means of compaction was required. Along with the all new 'T' type chassis, S&D introduced the Pakamatic. An aluminium body, to reduce gross vehicle weight, was loaded by a continuously-reciprocating pressure plate in the rear hopper. Produced under license from the French Rey design, again S&D produced a market leader, at one time achieving 60-percent of the British market, as well as considerable export sales.

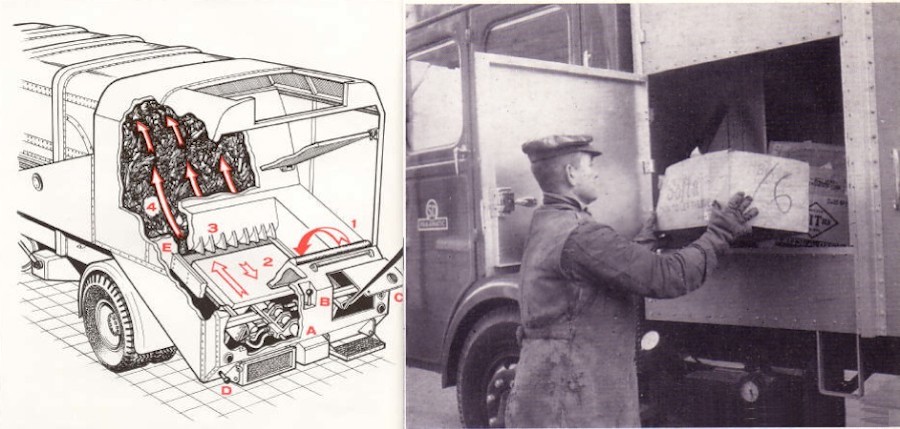

Pakamatic method dates to the 1930s, as first built by Fernand Rey. Refuse is loaded by hand over rave (1); 'Inverted Drawer' reciprocating packer ram (2) moves continuously to push rubbish into body, powered by a single hydraulic cylinder at (A); As refuse passes from hopper into body, it is forced under fixed tines (3) which help shred bulkier items, and retain load already within body (4). Optional side body door allows hand loading during the beginning of collection route

|

Left: Pakamatic shown with tailgate removed reveals high density refuse load

Right: With tailgate raised, Pakamatic tips to discharge load

One of the disadvantages of the design was the inherent instability, when the body was tipped for discharge on the difficult conditions of landfill sites. In 1969, a Paka Ejector prototype was produced to overcome this problem, using a hydraulic ram and plate to eject the refuse, rather than by tipping the body. It would ultimately be used with the next generation SD packers introduced in 1971.

Pakamatic was easily adapted for 'dustless' bin lift, while bulky items could be loaded in hopper side doors

10/1/04 (Revised 8/16/19)

© 2004, 2010

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|