The Semex series was introduced in the mid-1950s to replace the OSEM

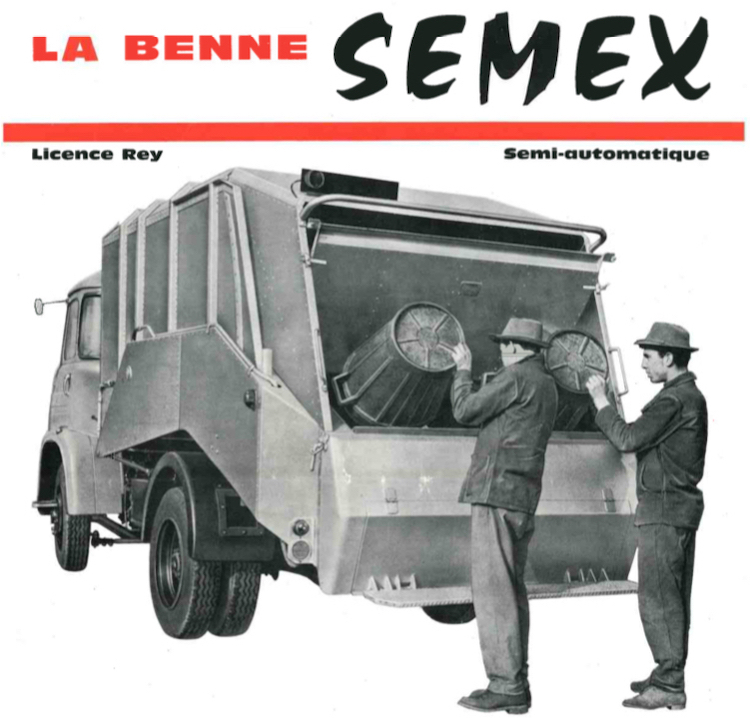

The Semex was a mid-1950s replacement for the OSEM, a pre-war design which was looking increasingly dated. In reality, the Semex was very similar in function to its predecessor, an intermittent ("semi automatique") loader with no follower plate behind the blade. Although not as efficient as the continuous-cycling "inverted drawer" packer of the Benne Rey models, the Semex had a rather deep hopper, accommodating fairly large loads before cycling was needed.

The Semex added the new tailgate lift arm-and-link mechanism used on the Rey models, eliminating the over-roof cable used on the OSEM. This feature makes distinguishing the Semex and Rey models somewhat difficult, without seeing the loading hopper. Basically, the Semex was marketed as an economical and low-maintenance compression body for hand-loading refuse. A variety of body sizes to 40-cubic meters were offered. Bin lift systems were not well suited to the Semex, due to its lack of follower plate, requiring an upgrade to the Rey model.

The Semex was 'batch loading' or 'intermittent' type of packer, which simply means that small batches of refuse were loaded into the hopper, and when filled, the packer blade was cycled to clear the hopper and pack the refuse. No refuse could be loaded until the blade had returned to a point near the loading or 'home' position. A hopper cover (not shown on the examples below) could also be closed to prevent refuse from spilling over and becoming lodged behind the blade.

This is the very same concept used on the early Ochsner and SEMAT 'OSEM' type rear loaders. In a larger size and different configuration, this method is still used on virtually every modern front loader today. With this type of packer, container dumping is possible, but the operator must be careful not to allow refuse to fall into the space behind the working face of the blade. In any case, the space behind the blade requires frequent cleaning to allow full retraction.

LEFT: Semex with packer blade retracted, and ready for loading refuse into hopper. A large metal enclosure covers the hydraulic cylinder

which projects into the hopper area, forming a partition. This partition is attached to, and moves with the packing blade.

RIGHT: Semex hopper with packer blade extended, pushing refuse out of hopper and into the body. The chrome-plated rod end of the

hydraulic cylinder is now visible, while the piston end has moved (with the blade) and projects into the body. Note the lack of follower plate

to prevent refuse from falling behind the blade, which made continuous loading and sealed bin lift systems impractical for use on this type of packer.

|

1950s Semex 'Rue Etroite' (narrow street) version, with hopper cover in closed-packing position

Larger 1960s-era Semex with hopper cover opened in loading position

3/24/20 (Revised 5/9/20)

© 2020

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|