L-R: Monsieur Colin (Chief Engineer, SEMAT), Tom Tillson (Chief Engineer, Shelvoke & Drewry Ltd.), Monsieur Fernand Rey (Managing Director, SEMAT), Stan Quin (Managing Director, Shelvoke & Drewry Ltd.) and the Lord Mayor of La Rochelle, France Rey's visionary designs were influential well beyond the borders of France, and his 30-plus years in the industry. His Rey Loader and its successors were a major force in the European market throughout his lifetime. The Superpac would be the crowning achievement to an already remarkable career, if only posthumously. His inverted-drawer short-stroke packer is the baseline from which modern drop-frame side loaders evolved. That his name and achievements in this industry are not better known is a grave injustice. It is hoped that this short history will help to correct this oversight in some small way, for he is probably the single most important inventor of refuse collection equipment who ever lived.

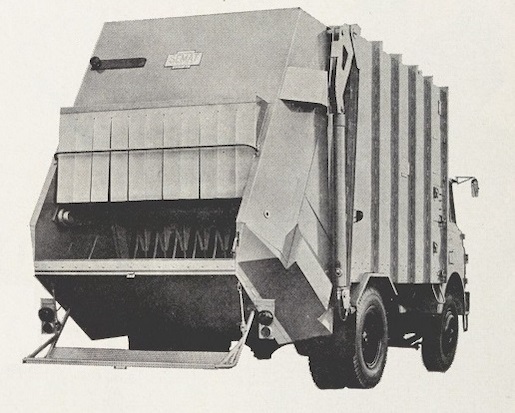

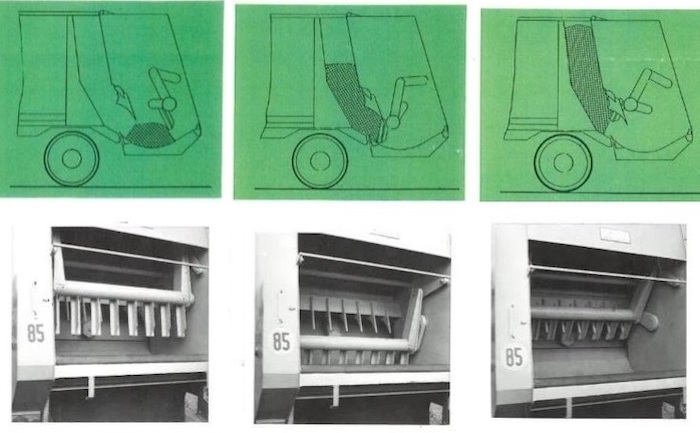

1969 SEMAT Superpac "Narrow Tine" The first documented SEMAT Superpac was produced as early as 1969, and used a rake with elongated tines which seems to have been powered by hydraulic cylinders on either side of the tailgate, operating crank arms pivotally connected to the rake assembly. A pair of swinging stabilizer links inside the hopper controlled the arc of the mechanism. Little is known of this version, and it is considered to be very rare and possibly only a prototype.

Note the narrow and elongated tines of the early Superpac, and the position of the stabilizer link low in the hopper

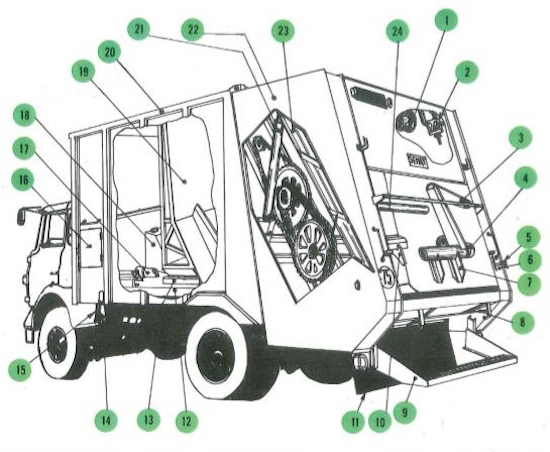

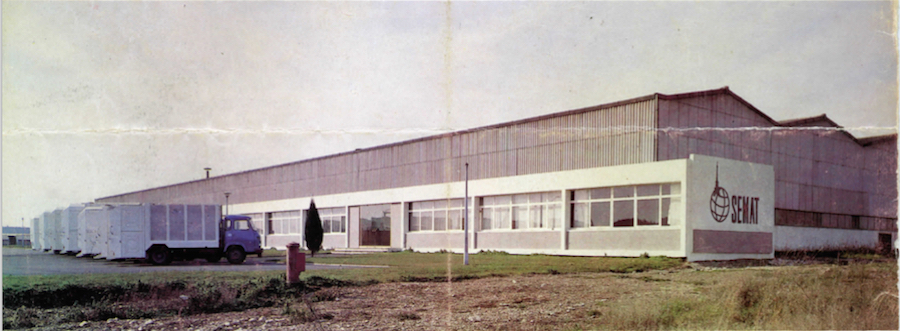

The Superpac was the first SEMAT to feature ejection unloading, with a telescopic cylinder mounted horizontally at floor level. The front of the body was partially open for access to the ram, with a steel panel covering only the uppermost section. The ejector blade was positioned rearward at the beginning of each load, and moved forward as the body filled and pressure increased. The Semex and Rey models were continued, but neither was fitted with ejection, being lower compaction designs. It was probably deemed unnecessary, and would only have added to the weight and expense of those bodies. The Superpac would be SEMAT's packer for the 1970s, and further engineering effort would be mostly applied to the new model. The partnership with Shelvoke and Drewry Ltd. continued, with the Superpac design being produced in England as the SD Revopak. Although of entirely different manufacture, both the Superpac and Revopak were functionally identical, and readers are referred to the SD Revopak album here at CRT for details on that variation. Also in 1970, production of SEMAT equipment was transferred to a new factory at La Rochelle. The old Versailles shop functioned as a parts & maintenance division for a time, before also being transferred to a new technical center at Dourdan in 1973. Two subsidiaries were started in Spain and Portugal. By the mid-1970s, SEMAT would become the number one refuse body builder in France, with a 50% market share, and ranked among the top ten producers worldwide.

Most Superpacs were built at the LaRochelle production center, which opened in 1970

SELECTED PATENTS

|