Colin's 1972 patent described a new rake guide method, which used slotted guides and slide blocks to replace the stabilizer linkage. There is no evidence that this ever went into regular production, and the familiar and reliable linkages were carried over from the original Superpac to the BR series. The only change was the pivot pin location, which was moved farther inside the hopper and away from the loading area. Ejection unloading was standard, and the body sheetmetal gained horizontal stampings for added rigidity. Mechanically, the Superpac BR would remain mostly unchanged over its remaining lifespan, which would extend into the 1990s. Superpac BR mechanism in operation (Video courtesy of Michel Ferro)

Larger chain-drive model Superpac beside a smaller version of the new Superpac BR. Note differences in hopper structure and position of upper links

This Superpac was from Germany and is mounted to a Magirus-Deutz tilt-cab

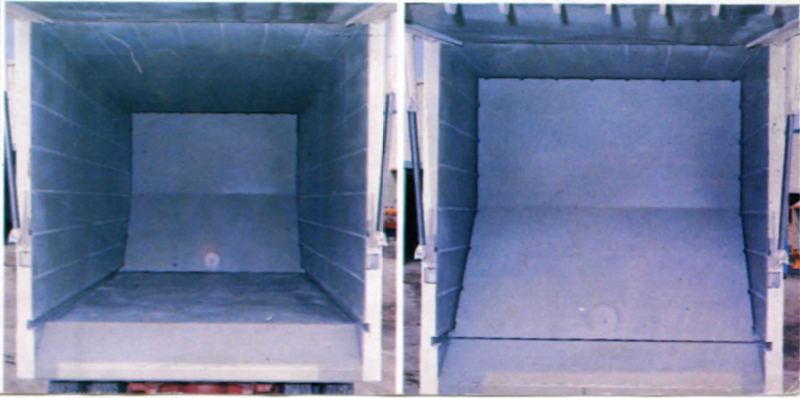

Tailgate raised, and ejector panel fully rearward after discharging load

Body interior

Side view of 1983 SEMAT Superpac BR4. Vertical ribs were stamped into the body sides on later models SELECTED PATENTS

|