Truxmore Industries

Buffalo, New York and Richmond, Virginia

By Eric Voytko

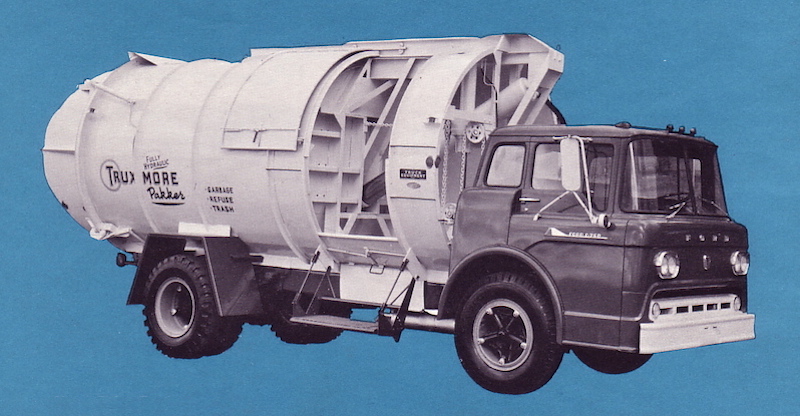

Truxmore Pakker

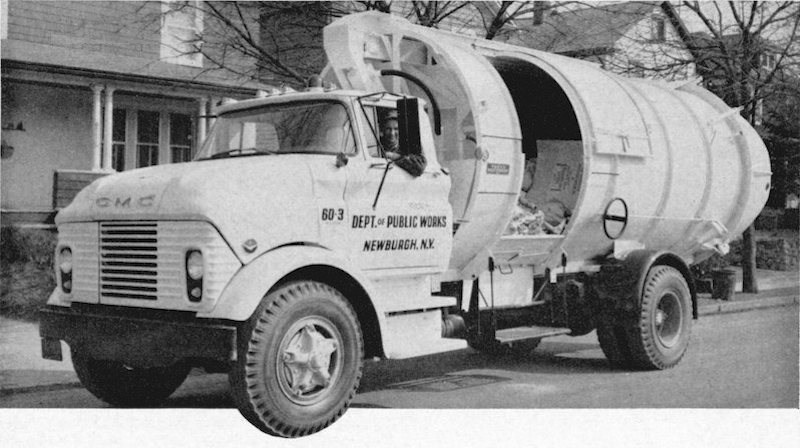

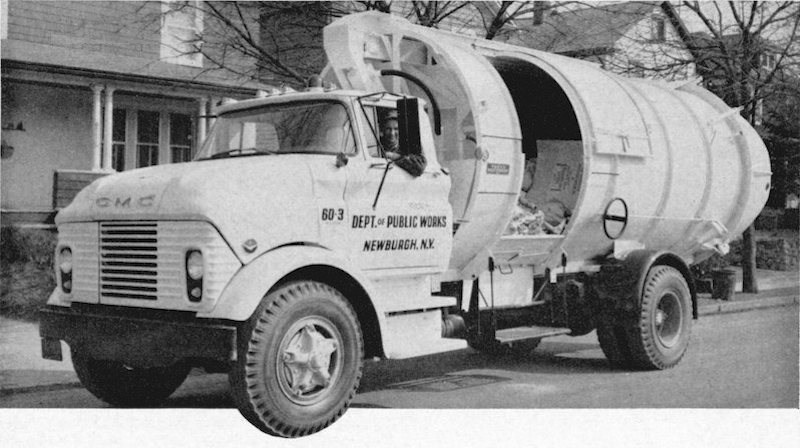

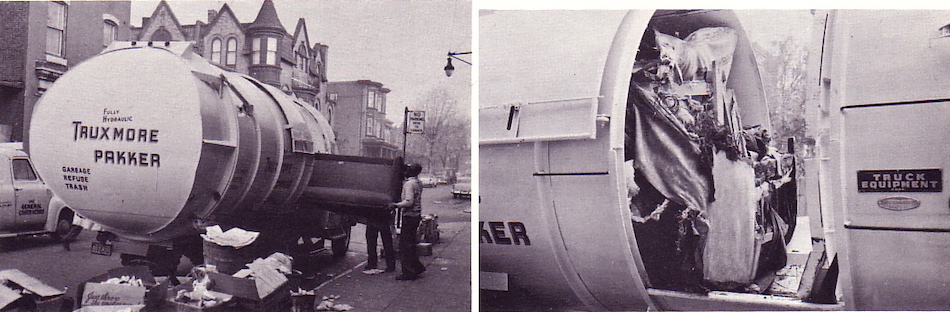

1960 Truxmore Pakker (23 cubic yard) on GMC LCF chassis

Truck Equipment Company of Buffalo, New York introduced the Truxmore Pakker body in 1960. This barrel-shaped truck was initially available in 18 and 23 cubic yard capacities, with bubble tailgates. The Pakker was the first American barrel truck to feature a hydraulically powered packer plate, having arrived a full year ahead of hydraulic versions from its close competitors, Pak-Mor and Seal-Press.

Truck Equipment Company had been in business since 1921, and was famous mainly for their Truxmore "third axle" sets that increased the load capacity of two-axle trucks. Their Richmond, Virginia office had been a Pak-Mor distributor during the 1950s, and thus had a well established refuse body sales operation. During the 1960s, they would help make the Truxmore Pakker one of the most popular bodies in the southeast United States. The Richmond branch would also later become involved with manufacturing a well. The simple but rugged circular packer was priced lower than rear loaders, but packed an awesome payload with its hydraulic power. 600-700 pounds per cubic yard was the advertised figure, and it delivered. Bulk objects that would stop some rear loaders were swallowed whole and crushed in the Truxmore, and full ejection unloading was a huge selling point, since ejection rear loaders were almost non-existent at the time.

Early model Pakker; note reeving hoist & chain at right front of body, which was used for blade retraction

The first version Truxmore Pakker (1960-62) used an angle mounted, single acting telescopic cylinder to power the packing blade. The big end was pivotally mounted to the upper front of the body, while the small end was affixed to the lower portion of the packer panel. The panel was guided by dual-rail roller tracks on the floor, assisted by a large upper guide rail attached to the inside top of the body. Fluid pumped into the big end of the cylinder caused the sections to expand, moving the plate against the load. Since the single-acting cylinder had no built-in means of retracting, a small ram attached to a reeving hoist and chain was used to withdraw the packer plate to the front of the body. To be sure, this was an unusual arrangement, and the patent application stated that the reason for this design was for a rapid return of the panel, resulting in a shortened packing cycle. As is apparent, side loaders of this type have no 'reload time', which is to say that no refuse may be added to the hopper until the entire packing cycle (including retraction) has been completed.

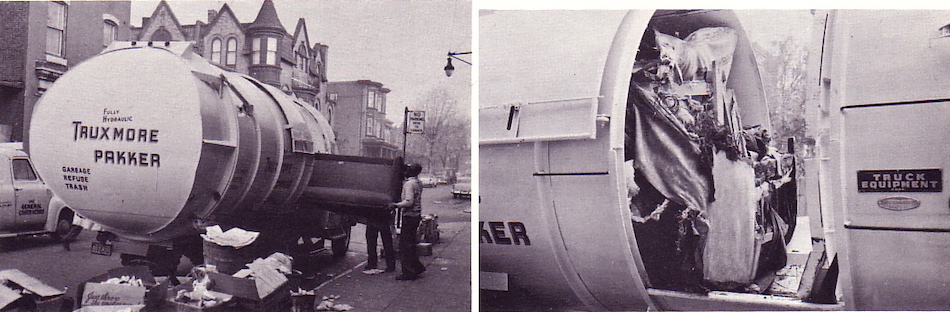

Furniture is easily loaded, and reduced to splinters by the powerful packing blade

The bubble tailgate was hydraulically powered, and a wheel-controlled remote latch release helped prevent injuries by keeping men away from the back end during the unloading process. The tapered shape of the tailgate also assisted in more uniform loading of the body. It worked in conjunction with the angled face of the packer panel, and the curvature of the body itself, to force refuse upward and thus eliminate air pockets in the body. The lower edge of the packing panel extended past the end of the body and into the tailgate bubble.

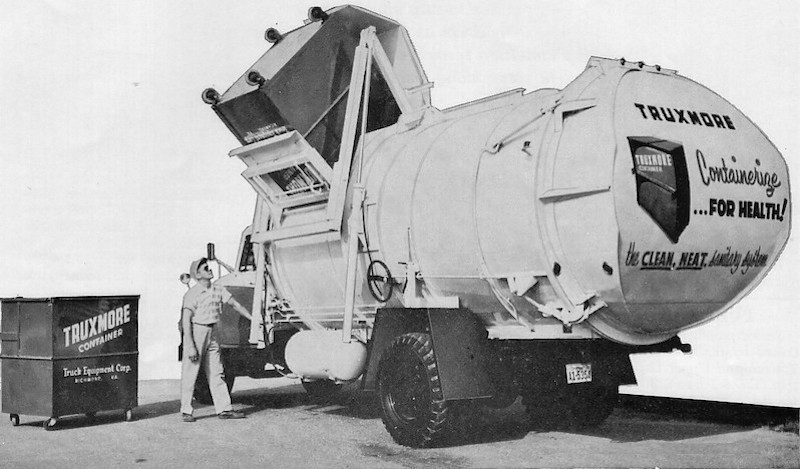

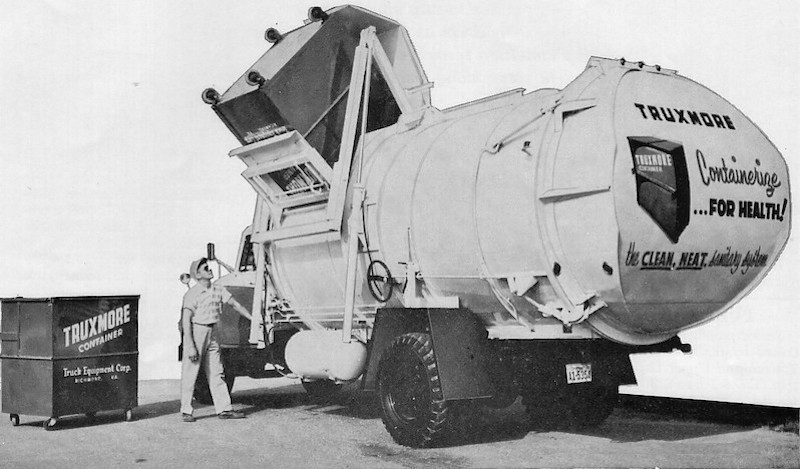

An all-hydraulic container hoist was offered from the beginning, allowing side pickup of containers from one to four cubic yards capacity. On bodies equipped with the container hoist, a loading door on the opposite side allowed for manual loading when needed.

Early model 18-yard Pakker owned by Donno Company of Long Island. Note the wheel on the body, which operates the tailgate latches remotely

Another Donno Truxmore, with loading door opened. Truck is a 1961 Chevrolet Viking.

Truxmore with container loader. The back of a Truxmore body was like a giant billboard

First generation Truxmore Pakker pushing out its load at the dump

The Next Generation Pakker (1963)

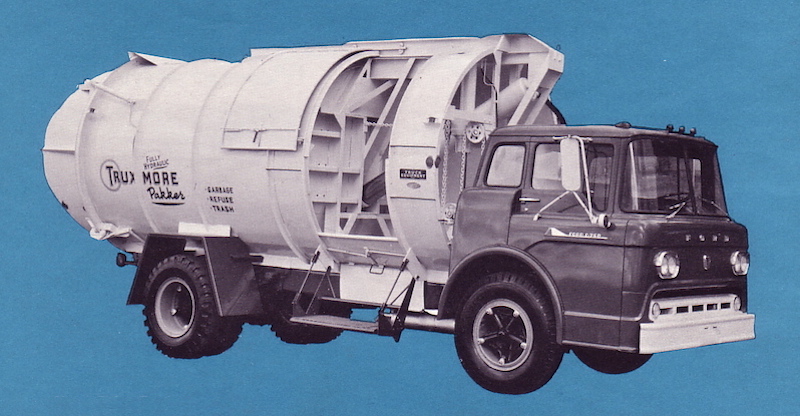

1964 Truxmore Pakker (14 cubic yard) on International Loadstar

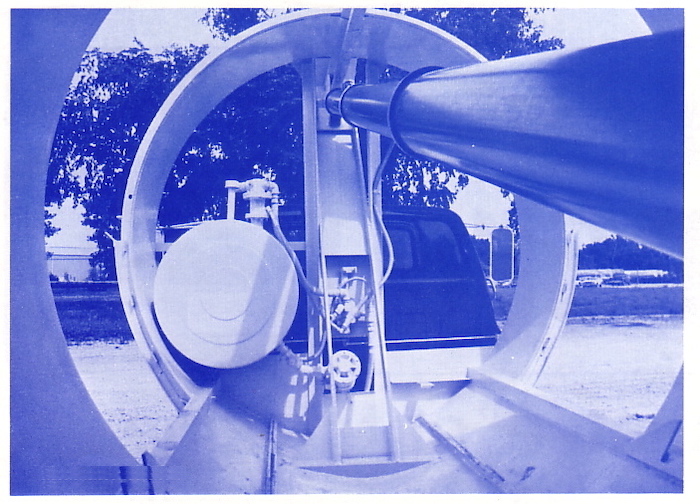

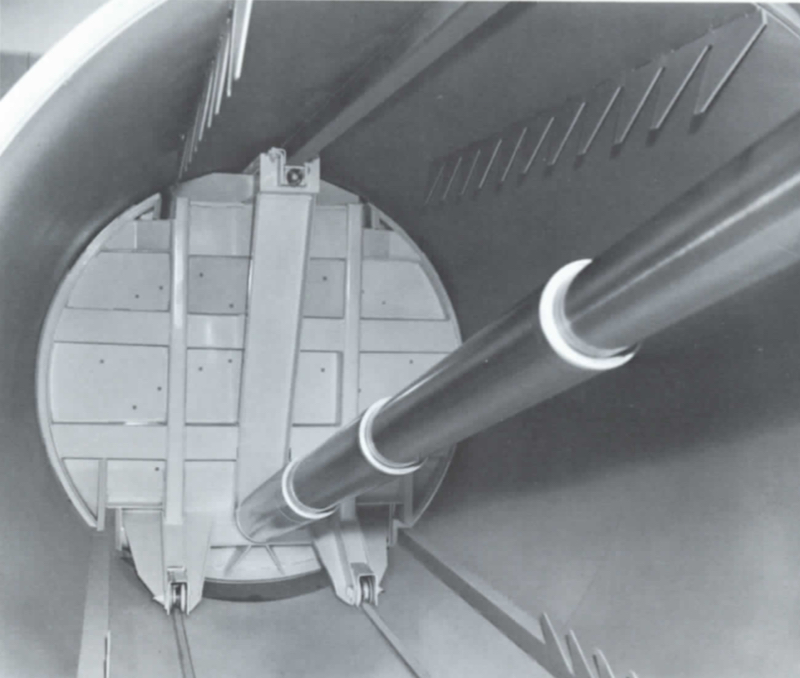

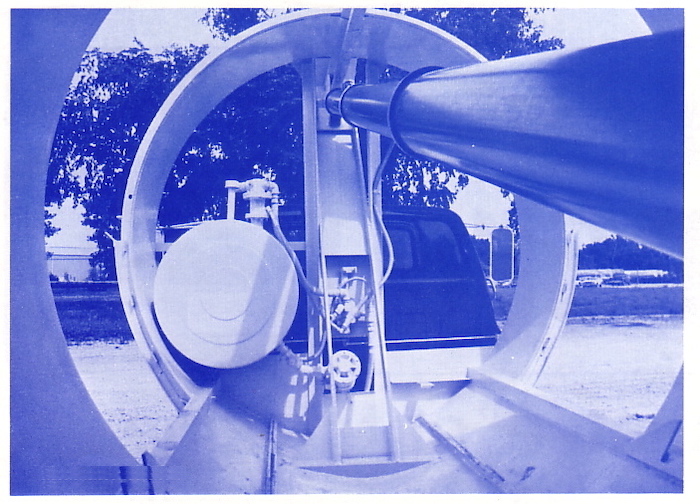

For 1963, the single acting telescopic packer ram was replaced with a double-acting type. This eliminated the need for the reeving hoist retraction mechanism, greatly simplifying this excellent design. The packing cylinder was angle-mounted as before, but the big end was now mounted to the blade, with the most powerful stage going into action last. Sectional overlap, critical for seal longevity on telescopic rams, was over two times the minimum design requirement, for a total of 65 inches.

Two new body sizes were added to the Pakker line up; a compact 14-yard version, and a massive 32-yarder, ideally suited for large container routes. The "Big 32" was eventually replaced during the mid-1970s by a 27-yard version for big volume haulers. The "full-size" 14-yard body was deleted when low-profile models were introduced in 10 and 15-yard capacities.

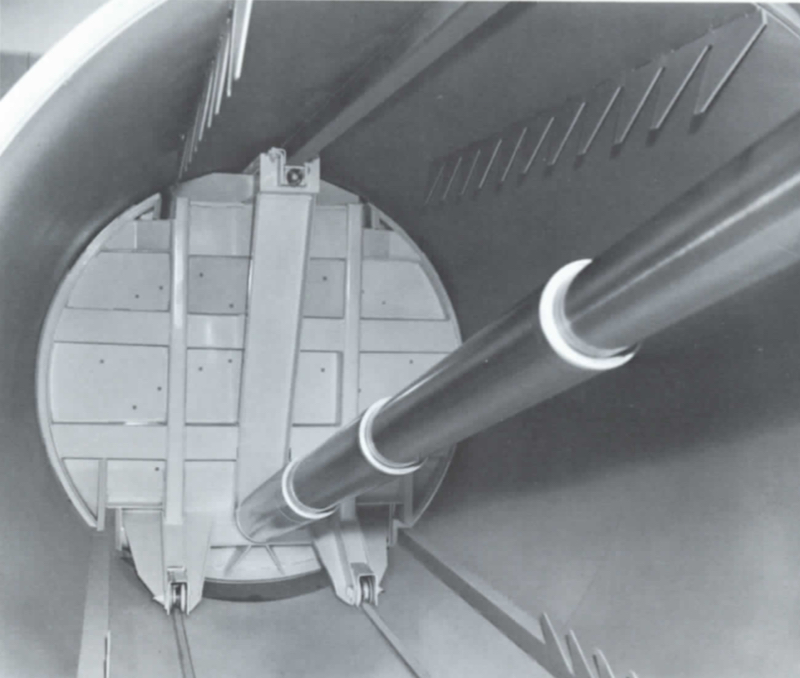

The new style packer plate and ram. Note the serrated load-stays on body floor and ceiling

Packing blade extends past edge of body and into tailgate

'Blade's eye' view shows the simple plumbing and hoses of this clean design

Blade clearing hopper area and entering body

The "Big 32" arrived for 1963, utilizing the redesigned cylinder and blade.

A 23 yarder owned by a New Jersey municipality pushes out its load at the incinerator

Certain types of refuse would emerge from a Truxmore as a near-solid core!

The 23-yard manual side loader was the workhorse for many small haulers in the 1960s and 1970s

18-yard model with container loader on Dodge A-Series cabover

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US3148786A |

Refuse compacting vehicle body |

Boeck, et.al. |

Truck Equipment Co. |

May 11, 1960 |

|

US3189378A |

Rear door latching means |

Boeck, et.al. |

Truck Equipment Co. |

May 11, 1960 |

|

US3207336A |

Refuse compacting vehicle body |

Boeck, et.al. |

Truck Equipment Co. |

January 16, 1964 |

4/5/09 (Updated 12/08/24)

© 2009

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|

|