Container loader remained popular, and hopper opening was widened during 1960's

By the 1970s, The a 27-yard body replaced the Big 32 as the king of the Truxmore lineup

At the other end of the scale, the "Tecorp 10" arrived around 1970 for scattered and rural routes, or restricted spaces. This low-profile series had it packing ram anchored to the bottom of the body, instead of the top as on full-size models

In 1973, Truxmore became one of the first manufacturers to promote the USS Roll-A-Waste cart system

"Truxmore 15" arrived around 1974, an elongated version of the Tecorp 10. This one has a Trux-Tilt bin lift to empty Roll-A-Waste carts

The USS Roll-A-Waste cart was one of the first semi-automated systems; note the operator holds the lid in his left hand

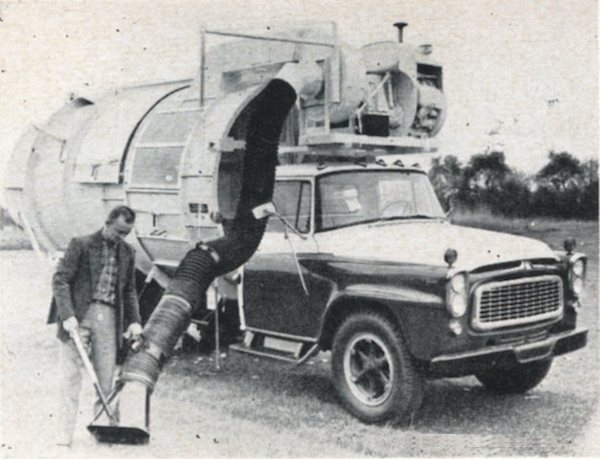

Vacuums were offered from the very first years, such as this leaf loader from 1961. Due in part to the location of the packer blade return cylinder on these early models, the engine and fan were mounted over the cab

The revamped '63-and-up Truxmore Pakker had more dead space in front of the packer panel, and here we see the vacuum unit has been 'shoe-horned' into the body

Easier access for service is probably what dictated situating the vacuum on the truck frame, between the cab and body. The 27 yarder on the right has had its vac assembly removed

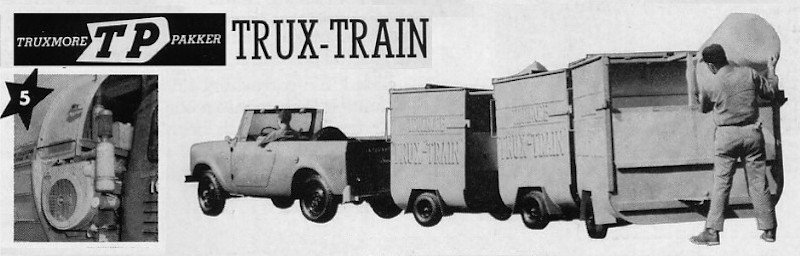

At left, a V-4 Wisconsin engine option for packing "on-the-go". At right is Truxmore's version of the train system for residential collection. A "mother" truck would empty the containers after crews had filled them

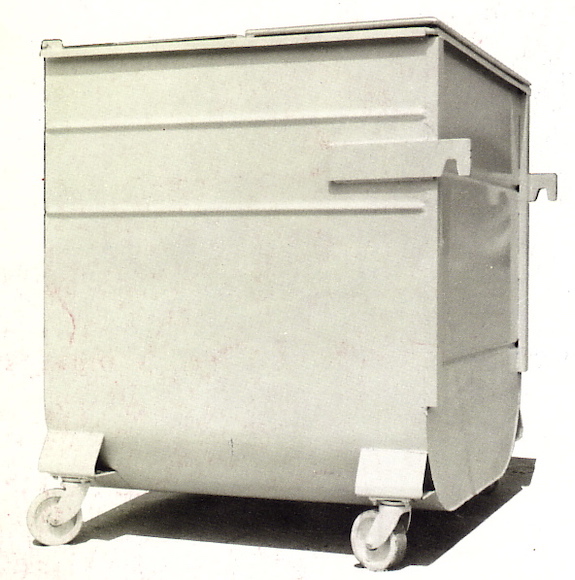

Truxmore containers, available in six sizes, from 1-4 cubic yards, were once a familiar site in the eastern United States

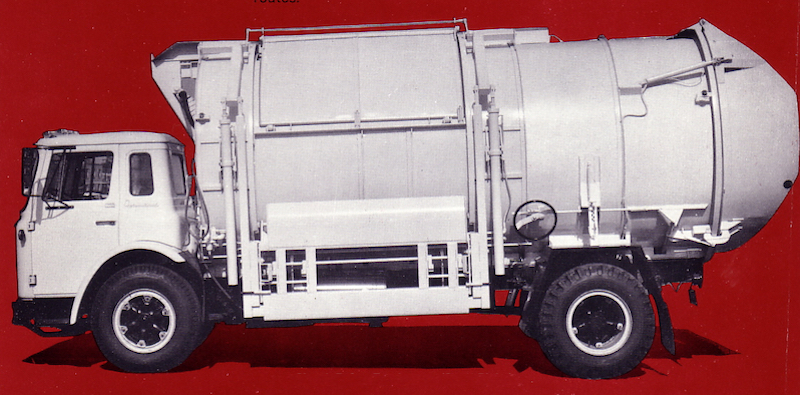

27-yard Pakker with container attachment at the Richmond factory

18-yard Pakker on 1977 Ford owned by Cummings Refuse Service of Hurricane, West Virginia

27-yard Truxmore Pakker on a hand-loaded residential route. During the 1970s and 1980s, these were among the largest packers around, and were far cheaper and easier to maintain than a rear loader. With a 600 lbs+ per cubic yard capability, they were popular with small independents and municipal outfits alike. However, with the skirts raised at the end of the route, loading height was almost as bad as an old open bodied truck.

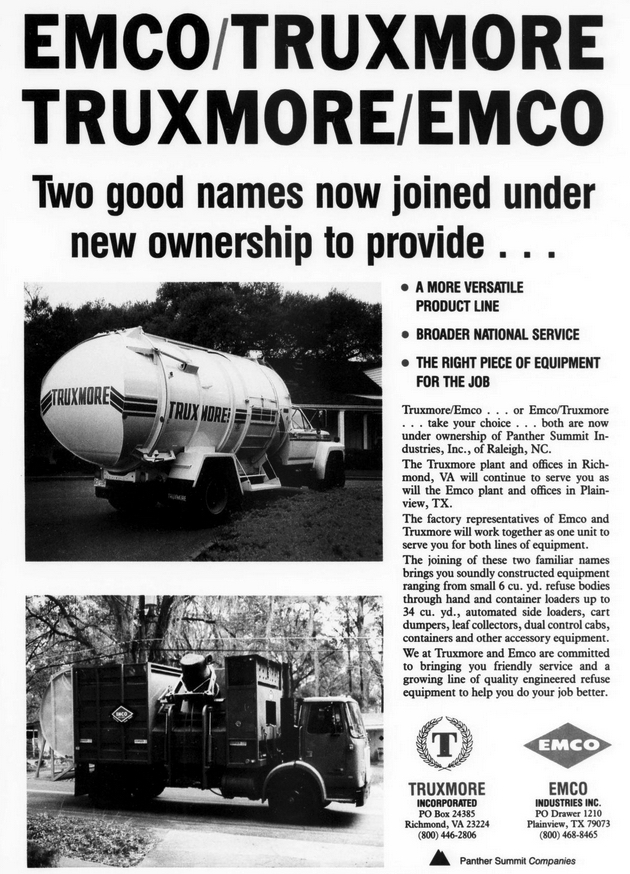

1986: Truxmore and EMCO are purchased by Panther Summit Industries

4/5/09 (Updated 12/08/24) © 2009 All Rights Reserved Photos from factory brochures/advertisements except as noted Logos shown are the trademarks of respective manufacturers |