Seal-Press and Tampo

San Antonio, Texas

By Eric Voytko

Seal-Press Side Loader

Seal-Press began building their refuse body in 1954, a circular side loader with a cable-driven packer plate. Externally, it was remarkably similar to the Pak-Mor product, which was being built a few short miles south of the Seal-Press plant in San Antonio. Above is a photo of a fleet of Seal-Press packers purchased by the city of Laredo, Texas in 1956. From the front they could easily be mistaken for Pak-Mor bodies.

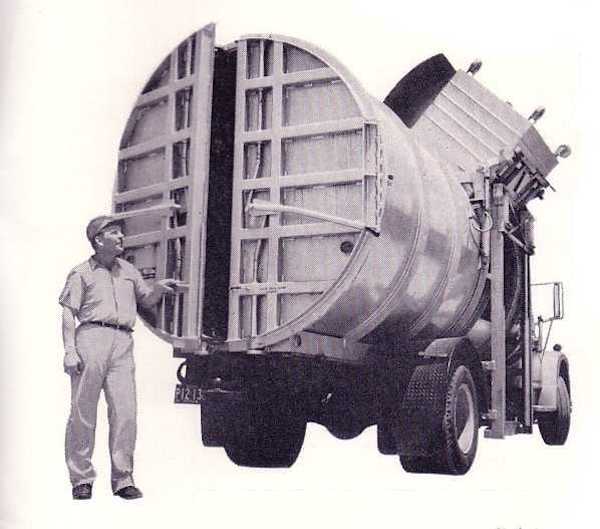

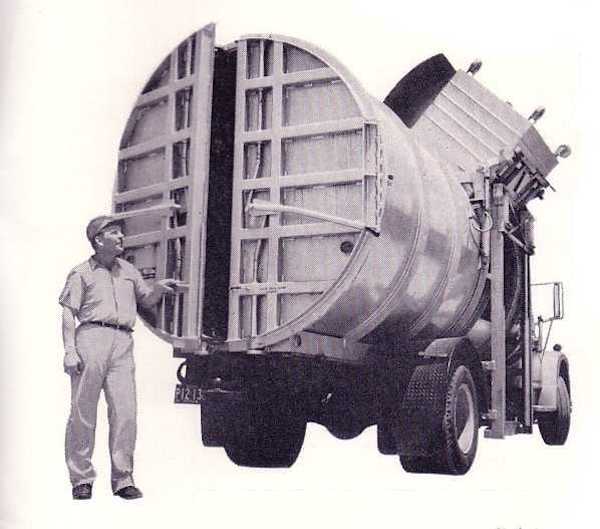

However, the rear view reveals the easy way to identify the early Seal-Press, which had a reverse-slant to the rear of the circular body. Instead of barn doors, a top-hinged, one-piece tailgate was pushed open by the load during ejection. The slant of the body coincides with angle of the packer plate, designed to force the compressed load upward during the pack cycle, minimizing air pockets and dead space.

HYDRAULIC SEAL-PRESS

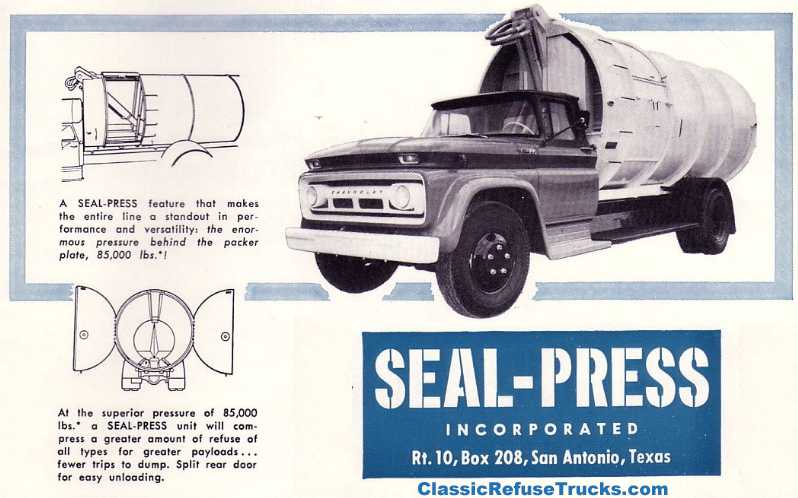

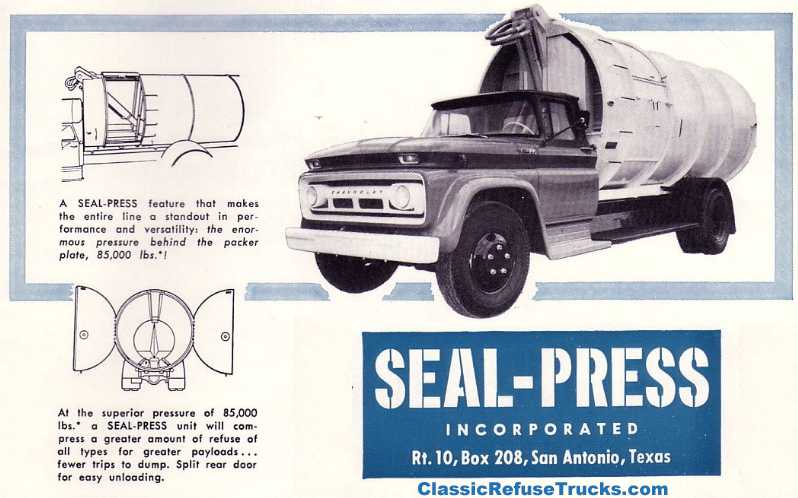

An all-hydraulic Seal-Press arrived in mid-1961, just months before the release of the H-series from rival Pak-Mor. The new Seal-Press units featured an angled packing cylinder delivering 85,000 pounds of force, and conventional barn-type rear doors. A container lift (all hydraulic) was also offered on the new '61 Seal-Press units.

Seal-Press side load container attachment

Barn doors replaced the one-piece end gate of earlier models

New Orleans, Louisiana bought several of the new hydraulic Seal-Press packers in 1962

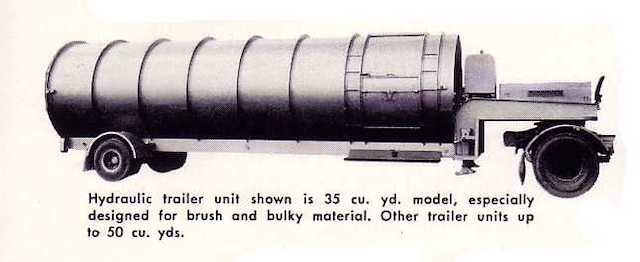

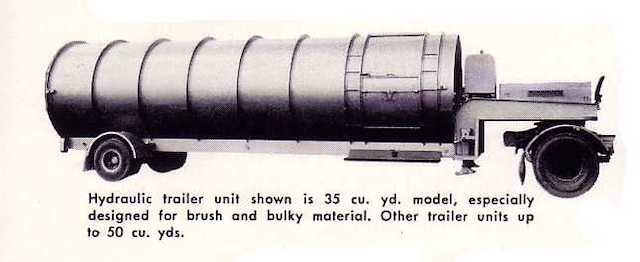

Semi-trailer compaction units were offered as shown above

Seal-Press hydraulic side loader owned by Greenville, Mississippi

Tampo Manufacturing

Seal-Press was bought by Tampo Manufacturing, also of San Antonio, in 1964. Tampo made road construction equipment, and had been in business since 1939. Seal-Press became an autonomous division of Tampo, and retained its original trade name, at least initially. Few changes occurred within the Seal-Press line until about 1968, when a rear loader was added.

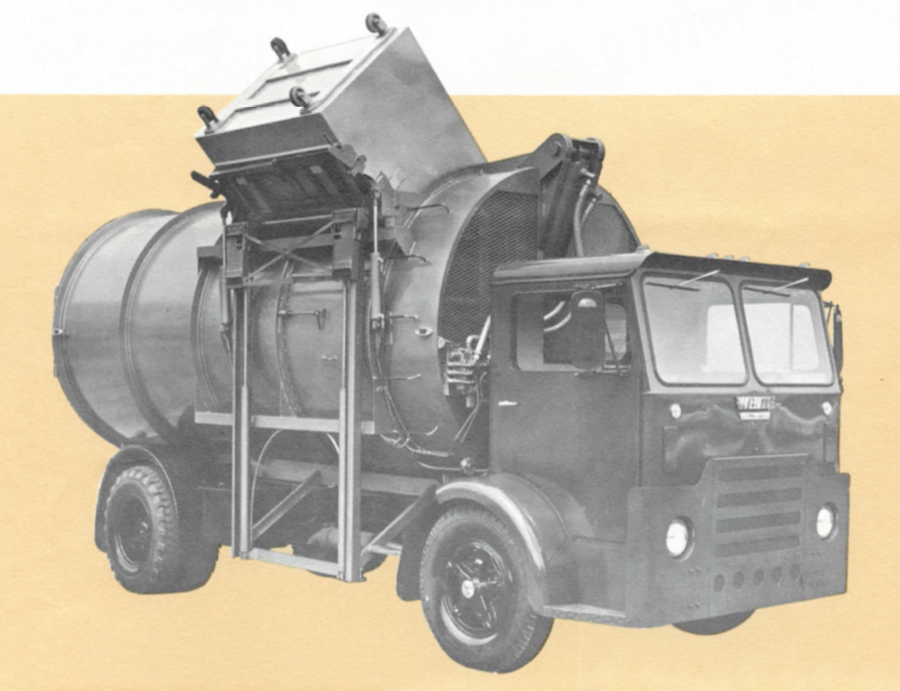

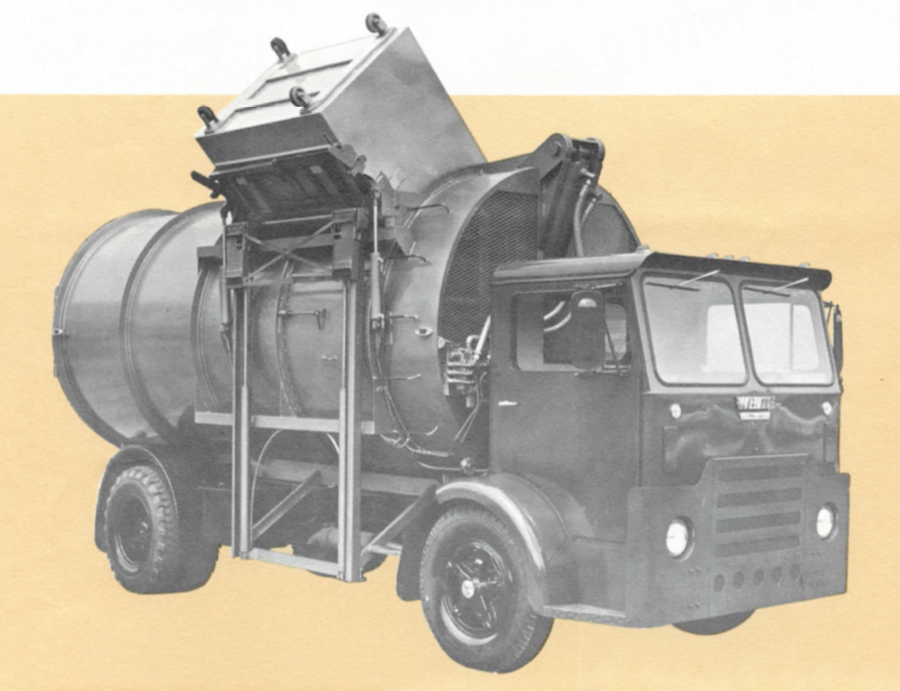

This new model was badged as a Tampo product, and had a 1.5-cubic yard hopper and electric packing controls. Body sizes available were 15, 20 and 25-cubic yards capacity. The rotary sweep panel was conventional enough for its day, being driven by a hydraulic motor, similar to the type used on Gar Wood models. However, the packing panel arrangement was in fact quite unique to the Tampo.

Seal-Press was bought by Tampo Manufacturing, also of San Antonio, in 1964. Tampo made road construction equipment, and had been in business since 1939. Seal-Press became an autonomous division of Tampo, and retained its original trade name, at least initially. Few changes occurred within the Seal-Press line until about 1968, when a rear loader was added.

This new model was badged as a Tampo product, and had a 1.5-cubic yard hopper and electric packing controls. Body sizes available were 15, 20 and 25-cubic yards capacity. The rotary sweep panel was conventional enough for its day, being driven by a hydraulic motor, similar to the type used on Gar Wood models. However, the packing panel arrangement was in fact quite unique to the Tampo.

As can be seen above, the sweep panel is suspended by four swinging links, instead of the usual fixed pivot bearings as used by Gar Wood and Pak-Mor. The uppermost links are mounted just outside of the tailgate side walls. Massive vertical hydraulic cylinders connect to these links, imparting motion to operate the panel. With tailgate latches released, the cylinders extend further to raise the tailgate for unloading. Thus, only three cylinders were used on the entire body; two packing/tailgate cylinders, and a third for the ejector panel.

By 1972, side loaders were badged as Tampo models, and added bubble tailgates, and body capacities of up to 35-cubic yards. All of the refuse bodies appear to have been dropped from production altogether by mid-decade.

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US2777588 |

Refuse truck with packer and ejector plate |

Williams |

Seal Press Inc. |

June 14, 1954 |

4/5/09

© 2009

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|

|