SIDE LOAD PACKERS

by Eric Voytko

The versatile side-loading packer truck has proven itself over many decades to be a design that can stand the test of time. From the dawn of the motor truck right up to the age of automated collection, these trucks have proven their worth and adaptability. Side load packers work under a very simple theory of operation: load refuse at the front and shove it backward with a moveable partition. There can't be much doubt that this method was spawned by the use of "templates", or "false fronts" in the earliest horse drawn wagons. These templates were placed at the front of the wagon prior to loading, and had chains or ropes affixed to either side. To unload, the chains were harnessed to a horse or truck, which pulled the plate rearward and scraped out the load. Alternately, the chains could be secured to an immovable object, and the wagon then pulled forward achieving the same result. This primitive form of "ejection discharge" was still used by some municipalities to unload garbage trucks right up to the 1940s. While efficient and inexpensive for its time, it still did nothing to compress bulky loads.

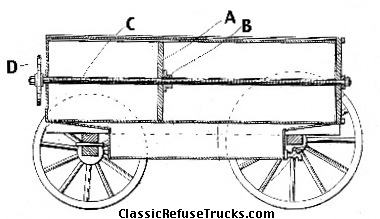

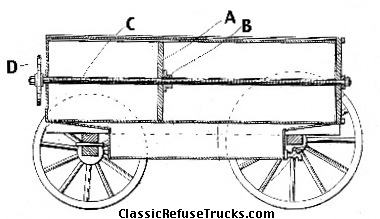

One of the earliest refuse packer designs (see illustration) dates to an era when the term "horsepower" accurately described the propulsion method of most refuse vehicles. A.G. Sharp of Bethesda, Maryland, filed this patent in 1907 for a refuse wagon that would be predictive of  things to come in that the moveable partition both compressed and discharged the load. Sharp's all enclosed, steel bodied wagon had a sliding ram panel (A) to which was affixed a nut (B). A rotating screw (C) passing through the nut causes the panel to move forward or backward depending on direction operator turned wheel (D). Refuse was loaded at the front of the wagon through a top opening, progressively compacted, and then ejected out the rear tailgate at the disposal point. In a 1912 patent, Sharp updated his design to a circular body to be mounted on a motor truck, with power supplied by the engine through triple screw drive. It is unknown whether Sharp's designs ever made it off the drawing board, but his concept of the side load packer truck gained prominence in the 1930s with the Marion Compressor, which would become one the first commercially successful packer trucks in North America. things to come in that the moveable partition both compressed and discharged the load. Sharp's all enclosed, steel bodied wagon had a sliding ram panel (A) to which was affixed a nut (B). A rotating screw (C) passing through the nut causes the panel to move forward or backward depending on direction operator turned wheel (D). Refuse was loaded at the front of the wagon through a top opening, progressively compacted, and then ejected out the rear tailgate at the disposal point. In a 1912 patent, Sharp updated his design to a circular body to be mounted on a motor truck, with power supplied by the engine through triple screw drive. It is unknown whether Sharp's designs ever made it off the drawing board, but his concept of the side load packer truck gained prominence in the 1930s with the Marion Compressor, which would become one the first commercially successful packer trucks in North America.

By 1945 and in the years following, other manufacturers began offering side load packers, with either winch or screw drive powering the packer plate. As with the Sharp's designs and the Marion Compressor, the majority were of the full travel design, with the packing panel also serving as a load ejector. Most notable would be L.A. LeLaurin's design which used a winch driven endless roller chain to operate the packer blade. Later known as Pak-Mor, it would become one of the most popular side loaders of all time, and hydraulic versions are still being built to this day. By and large, side load packers were simple designs which were relatively inexpensive to construct, and offered an alternative to buyers who sought the benefits of compression without the complexity of then-new rear load packer trucks. Moreover, these early designs with their mechanically driven packers could be repaired by any knowledgeable mechanic and no hydraulic experience was necessary. As the sanitary landfill began to gain prominence, the non-tipping full-eject feature would be appreciated on the poor footing of fill sites.

Side load packers would become the platform from which the first front-loading container trucks would be built during the 1950s. Dempster, the name most closely associated with detachable container systems, used a modified Pak-Mor side loader as the heart of their earliest Dumpmaster front loaders. The normally side loading body was merely fitted with a funnel-like opening to accept refuse dumped from overhead. Starting in the late 1950s, side-loading container hoist systems were also adapted to some established models like MB, Truxmore and Pak-Mor, typically handling containers of one to three cubic yards capacity.

As hydraulics became more universally accepted within the industry, side load packers began substituting fluid power for the old mechanical systems. Hydraulic power greatly increased the force that could be applied to the load, and again the advantage lent itself well to front loaders, with more powerful types arriving by the end of the decade. Another advance was that of the half pack type side loader in which the blade only travelled far enough to clear the hopper, relying on the build-up of material within the body for compression to begin. This method was actually not really new, having been pioneered in Europe by Jacob Ochsner and Fernand Rey in the 1930s. Well known applications of this method were produced under Rey/SITA and later SEMAT in France, as well as the popular SD Pakamatic and Dennis Paxit from Great Britain. This half-pack method began appearing in American side loader designs in the mid 1950s. Though some sacrifice in compaction density is made over full travel packers, half-packs are typically simpler and carry less dead weight, and therefore more legal payload. Full travel type packers could not be loaded until the packing cycle ended, and blade had returned to the front of the body. With few exceptions, half-pack types with their fast-cycling, short-stroke packer blades can be set for continuous loading/packing operation. It is this last feature that perhaps made them so ideally suited for the automated cart dumper systems which would appear by the end of the 1960s. Additionally, many front loaders began to employ half-pack bodies as a way to increase capacity without the excess weight associated with full-travel type packers.

What follows is by no means a complete list of every side load packer, rather it is merely a selection of various makes including early pioneers, some "lost classics", as well as some interesting contemporary designs. Please note that four major brands, Pak-Mor, Truxmore, Lodal , and

E-Z Pack are conspicuously absent, but can be found in their own separate albums here at CRT.

CCC Integrated Side Loader (ISL) CCC Album at CRT

CCC Integrated Side Loader (ISL) CCC Album at CRT

Crane Carrier Corporation (Tulsa, Oklahoma)

Although this is actually more of a latter day classic, these cylindrical giants deserve a mention, being among the ultimate expressions of side loader design on a truly monstrous scale. As its name suggests, the Integrated Side Loader was engineered and built as a complete unit by CCC, a longtime builder of specialized truck chassis. Like its cousins the IRL and IFL, which all shared the same circular body, the ISL had a unique arrangement whereby the packer blade cylinder projects over the roof of the low-mounted cab, eliminating any "cylinder bulge" in the plate and centralizing the hydraulic force. Note the placement of the radiator, above the cab at the top of the body.

|

COBEY HELIX/TITE-PAK Cobey Album at CRT

COBEY HELIX/TITE-PAK Cobey Album at CRT

Perfection-Cobey Company (Galion, Ohio)

Produced during the 1970s and into the early 1980s under the Athey brand name, this was a "hybrid" model featuring a continuous short-stroke packer blade combined with a detaching front partition inside the body which for full ejection unloading.

|

FASTPACK FastPack Page at CRT

FASTPACK FastPack Page at CRT

Data-Veyors Corporation (Oakland, California)

While not technically sophisticated, this 1970s entry was among many packers marketed to a segment of buyers sometimes overlooked by the bigger companies: Institutions, park authorities, and one-man operations could have "big truck" compaction without the immense size and costly investment. Such trucks were also marketed as "scatter route" and "missed stop" units to compliment fleets of full-sized packers. Available in 7.5, 10 and 13 cubic yard capacities and featured a three-stage telescopic packing cylinder.

|

GRACE PACKER W.E. Grace Page at CRT

GRACE PACKER W.E. Grace Page at CRT

W.E. Grace Company (Dallas, Texas)

The Grace packer was a short-lived design that was built in the years just after World War II, and was a screw-drive, full-travel packer much like the Marion. Note the triangular cover over the triple-screw drive mechanism, which immediately identifies this Grace packer working the streets of Dallas in 1946.

|

HAUL-ALL CURBSTER Haul-All Page at CRT

Haul-All Equipment Systems (Lethbridge, Alberta)

The Curbster is a compound-blade, drop-frame side loader utilizing a mechanism very similar to a famous rear load packer, the Heil Colectomatic. In fact, it even looks like a 1950s Colectomatic mounted backwards on the truck chassis and loaded from the side! This truck is used by the contractor serving Camrose, British Columbia.

|

HYDEPAK / HYD-PAK Hydepak Page at CRT HYDEPAK / HYD-PAK Hydepak Page at CRT

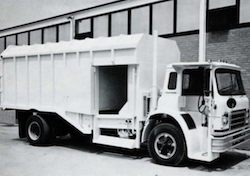

Hyde Corporation / Hobbs Trailer, Division of Fruehauf (Fort Worth, Texas)

Another Texas entry to side loader history was this Hydepak (or Hyd-Pak), a half-pack model that actually pre-dates the Shu-Pak, but was of conventional body-above-frame design. The Hyde-Pak was an all-hydraulic machine with a unique hinged panel partially separating the hopper from the main body for load retention. The 1956 model shown was from Jacksonville Beach, Florida. Following their purchase by Hobbs Trailer in the 1960s, the Hyde-Pak name also graced a full-eject side loader, a compaction transfer trailer and even a rear loader very similar to the Heil Colectomatic.

|

LEACH CURBCRUISER Leach Curbcruiser Page at CRT

LEACH CURBCRUISER Leach Curbcruiser Page at CRT

Leach Company (Oshkosh, Wisconsin)

During the 1970s, the big names in rear loading bodies were getting interested in side loaders, particularly the low-loading west coast types that were gaining favor nationwide. In an attempt to enter into this market, Leach Chief Engineer Cyril Gollnick, who had designed the revolutionary Packmaster and 2R Packmaster rear loaders, was tapped to design the firms first side loader. The Curbcruiser used essentially the packing mechanism of the Heil Colectomatic sawed in half, reversed, and moved to the front of the body. A sweep panel lifted refuse up out of the hopper, while a packing panel (integral with the ejector blade) swept the refuse into the body. The ejector panel was shaped to direct and balance the incoming load, as well as to crush and eject the load. With the low loading hopper slung over the outside of the truck frame, Leach seems to have arrived at a novel way of avoiding the use of a drop-frame chassis to lower the loading height. However, the hopper size was somewhat small, the opening restrictive and the truck could only be loaded on the right hand side. After a very short run, Leach abandoned their side loader in the early 1980s, but remained an industry leader in rear loader sales. A similar variation of this compound blade theme is currently built by Haul-All in Canada.

|

MARION COMPRESSOR Marion Page at CRT

MARION COMPRESSOR Marion Page at CRT

Marion Metal Products (Marion, Ohio)

The Marion Compressor utilized a screw driven packer plate to compress the load. Not to be confused with screw/auger type loaders, this was simply two long shafts with helical-cut grooves, mounted inside and running horizontally the length of the body. These "screws" passed through nuts in the packer plate so that when the shafts were rotated, the packer plate would slide rearward (or forward, depending on the direction of rotation). Traveling the length of the body, the packer plate both compressed and ejected the load. Though the internals are not visible in this 1935 photo, the cover for the screw drive mechanism is visible just behind the cab. This simple mechanical drive was tapped from the truck engine through a common PTO, but required no hydraulic system for loading or unloading. Marion Compressors were a great idea for their time, and had little competition (from side-load packers) during the pre-war years. Since the post-war period, the firm continued building a more modern hydraulic version, the Hydropaka up until |

MB PACKER M-B Album at CRT

MB PACKER M-B Album at CRT

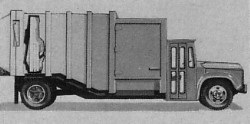

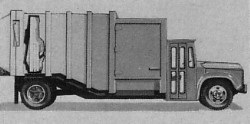

MB Corporation (New Holstein, Wisconsin)

The Meili-Blumburg Corporation entered the refuse truck business the early 1950s with this square bodied packer. The MB Packer had a mechanically controlled blade driven by a cable and pulley arrangement and powered by a PTO winch. In addition to the economical aspects of this mechanical packer, the firm also emphasized that the square body could double as a general purpose van in addition to hauling garbage. In the 1960s, an all-hydraulic Pack-King side loader was introduced with a compound blade system, as well as the Moto-Pack, a small portable tow-behind packer. The firm remains in New Holstein, but has not built refuse bodies since the 1970s.

|

McCLAIN OMSUL McCLAIN Page at CRT

McCLAIN OMSUL McCLAIN Page at CRT

McClain Industries (Utica, Michigan)

The OMSUL, or One Man Side Universal Loader, was a drop-frame half-pack design much like the Shu-Pak except with the addition of a full eject panel inside the storage body, which could also be use to crush the load as collection progressed. McClain eventually bought E-Z Pack and marketed drop-frame side loaders under that name.

|

NEW WAY MATE New Way Album at CRT

NEW WAY MATE New Way Album at CRT

New Way Manufacturing (Des Moines and Scranton, Iowa)

The New Way mate offered buyers six yard capacity and full ejection for a one-ton truck chassis. In addition to various compact side loaders for which it has become famous, the firm began selling rear loaders by the early 1980s and today offers a wide range of refuse equipment.

|

RAM-PAK Baughman Page at CRT

RAM-PAK Baughman Page at CRT

Baughman Manufacturing Company (Jerseyville, Illinois)

This truck, looking very similar to the Hyde-Pak , is from a 1960 advertisement.

|

SHU-PAK Western Album at CRT, Shu-Pak Album at CRT,

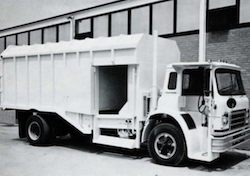

Western Body/Maxon Industries (Los Angeles, California) and Shu-Pak Equipment (Cambridge, Ontario)

John Shubin patented his side loader in 1958, which was produced under license by California truck body builder Western Body & Hoist (who were later bought by Maxon Industries).

The Shu-Pak was to revolutionize refuse collection in the west, and was a pioneer of the drop-frame, half-pack design. Shown is an early sixties model from Santa Clara, California. Like many cities, they switched to one-man operation with these trucks which were often combined with special walk-through cabs and dual steering controls. The Shu-Pak's short packer blade only travels enough to clear the hopper area, then returns to the front of the body. Each successive hopper load pushes the previous load further into the body, compaction occurring as the body becomes filled. Some models even used a "pre crusher" plate, which would flatten the load in the hopper prior to the primary panel packing stroke. Shubin borrowed an idea from 1930s era enclosed garbage trucks by using a drop frame, that is to say a modification of a standard truck chassis whereby the frame rails dip sharply just behind the cab. The hopper/packer blade rest in this "valley" resulting in an extremely low loading height, something conventional side load packers never came close to achieving. At a time when full ejection unloading was starting to sweep the industry, the Shu-pak did it the old fashioned way, by hoist dumping. Capable of a continuous packing cycle, the Shu-Pak was a great choice for automated loading systems when they began to appear in the late 1960s. Similar low-slung designs would follow by competitors such as Lodal, McClain, Amrep and Labrie, their popularity extending far beyond the west coast. Maxon no longer builds this body, but it is currently manufactured in Canada under the Shu-Pak brand name. The Shu-Pak was to revolutionize refuse collection in the west, and was a pioneer of the drop-frame, half-pack design. Shown is an early sixties model from Santa Clara, California. Like many cities, they switched to one-man operation with these trucks which were often combined with special walk-through cabs and dual steering controls. The Shu-Pak's short packer blade only travels enough to clear the hopper area, then returns to the front of the body. Each successive hopper load pushes the previous load further into the body, compaction occurring as the body becomes filled. Some models even used a "pre crusher" plate, which would flatten the load in the hopper prior to the primary panel packing stroke. Shubin borrowed an idea from 1930s era enclosed garbage trucks by using a drop frame, that is to say a modification of a standard truck chassis whereby the frame rails dip sharply just behind the cab. The hopper/packer blade rest in this "valley" resulting in an extremely low loading height, something conventional side load packers never came close to achieving. At a time when full ejection unloading was starting to sweep the industry, the Shu-pak did it the old fashioned way, by hoist dumping. Capable of a continuous packing cycle, the Shu-Pak was a great choice for automated loading systems when they began to appear in the late 1960s. Similar low-slung designs would follow by competitors such as Lodal, McClain, Amrep and Labrie, their popularity extending far beyond the west coast. Maxon no longer builds this body, but it is currently manufactured in Canada under the Shu-Pak brand name.

|

WILLOCK Willock Page at CRT

WILLOCK Willock Page at CRT

Willock Truck Equipment Co. (Vancouver, British Columbia)

Looking quite modern, this late fifties or early sixties side loader was actually a throwback to the old days, being of the screw-drive, full-travel type. The triple screw drive cover at the front of the body recalls the Grace Packer of the 1940s.

|

2/5/05

© 2005 Eric Voytko

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|  things to come in that the moveable partition both compressed and discharged the load. Sharp's all enclosed, steel bodied wagon had a sliding ram panel (A) to which was affixed a nut (B). A rotating screw (C) passing through the nut causes the panel to move forward or backward depending on direction operator turned wheel (D). Refuse was loaded at the front of the wagon through a top opening, progressively compacted, and then ejected out the rear tailgate at the disposal point. In a 1912 patent, Sharp updated his design to a circular body to be mounted on a motor truck, with power supplied by the engine through triple screw drive. It is unknown whether Sharp's designs ever made it off the drawing board, but his concept of the side load packer truck gained prominence in the 1930s with the Marion Compressor, which would become one the first commercially successful packer trucks in North America.

things to come in that the moveable partition both compressed and discharged the load. Sharp's all enclosed, steel bodied wagon had a sliding ram panel (A) to which was affixed a nut (B). A rotating screw (C) passing through the nut causes the panel to move forward or backward depending on direction operator turned wheel (D). Refuse was loaded at the front of the wagon through a top opening, progressively compacted, and then ejected out the rear tailgate at the disposal point. In a 1912 patent, Sharp updated his design to a circular body to be mounted on a motor truck, with power supplied by the engine through triple screw drive. It is unknown whether Sharp's designs ever made it off the drawing board, but his concept of the side load packer truck gained prominence in the 1930s with the Marion Compressor, which would become one the first commercially successful packer trucks in North America.

CCC Integrated Side Loader (ISL)

CCC Integrated Side Loader (ISL)  COBEY HELIX/TITE-PAK

COBEY HELIX/TITE-PAK  FASTPACK

FASTPACK  GRACE PACKER

GRACE PACKER

HYDEPAK / HYD-PAK

HYDEPAK / HYD-PAK  LEACH CURBCRUISER

LEACH CURBCRUISER  MARION COMPRESSOR

MARION COMPRESSOR  MB PACKER

MB PACKER  McCLAIN OMSUL

McCLAIN OMSUL  NEW WAY MATE

NEW WAY MATE  RAM-PAK

RAM-PAK  The Shu-Pak was to revolutionize refuse collection in the west, and was a pioneer of the drop-frame, half-pack design. Shown is an early sixties model from Santa Clara, California. Like many cities, they switched to one-man operation with these trucks which were often combined with special walk-through cabs and dual steering controls. The Shu-Pak's short packer blade only travels enough to clear the hopper area, then returns to the front of the body. Each successive hopper load pushes the previous load further into the body, compaction occurring as the body becomes filled. Some models even used a "pre crusher" plate, which would flatten the load in the hopper prior to the primary panel packing stroke. Shubin borrowed an idea from 1930s era enclosed garbage trucks by using a drop frame, that is to say a modification of a standard truck chassis whereby the frame rails dip sharply just behind the cab. The hopper/packer blade rest in this "valley" resulting in an extremely low loading height, something conventional side load packers never came close to achieving. At a time when full ejection unloading was starting to sweep the industry, the Shu-pak did it the old fashioned way, by hoist dumping. Capable of a continuous packing cycle, the Shu-Pak was a great choice for automated loading systems when they began to appear in the late 1960s. Similar low-slung designs would follow by competitors such as Lodal, McClain, Amrep and Labrie, their popularity extending far beyond the west coast. Maxon no longer builds this body, but it is currently manufactured in Canada under the Shu-Pak brand name.

The Shu-Pak was to revolutionize refuse collection in the west, and was a pioneer of the drop-frame, half-pack design. Shown is an early sixties model from Santa Clara, California. Like many cities, they switched to one-man operation with these trucks which were often combined with special walk-through cabs and dual steering controls. The Shu-Pak's short packer blade only travels enough to clear the hopper area, then returns to the front of the body. Each successive hopper load pushes the previous load further into the body, compaction occurring as the body becomes filled. Some models even used a "pre crusher" plate, which would flatten the load in the hopper prior to the primary panel packing stroke. Shubin borrowed an idea from 1930s era enclosed garbage trucks by using a drop frame, that is to say a modification of a standard truck chassis whereby the frame rails dip sharply just behind the cab. The hopper/packer blade rest in this "valley" resulting in an extremely low loading height, something conventional side load packers never came close to achieving. At a time when full ejection unloading was starting to sweep the industry, the Shu-pak did it the old fashioned way, by hoist dumping. Capable of a continuous packing cycle, the Shu-Pak was a great choice for automated loading systems when they began to appear in the late 1960s. Similar low-slung designs would follow by competitors such as Lodal, McClain, Amrep and Labrie, their popularity extending far beyond the west coast. Maxon no longer builds this body, but it is currently manufactured in Canada under the Shu-Pak brand name.

WILLOCK

WILLOCK